What is the Automated Drilling Solution

Overview

Halliburton real-time operations enables performance improvements at almost every step of the drilling process. Navigating drilling hazards requires ever-increasing levels of vigilance. Intuitive and user-driven, This application is a highly efficient real-time data monitoring application that gives you a consistent view of your drilling data across your operations as it comes in from the rig. It enables you to unlock an immersive real-time environment and collaborate with your team like never before.

Product Requirement Document

Dive deeply with business goals

Halliburton’s 3D Automated Drilling Solution Platform is a complex and innovative technology with the potential to revolutionize the oil and gas drilling industry. Its business goals can be categorized into three main areas:

UI/UX Challenges

Understand clearly

HAL Platform is a powerful tool with immense potential, but it also faces significant UI/UX challenges due to its complex nature and target audience. Here are some key issues to consider:

How to research

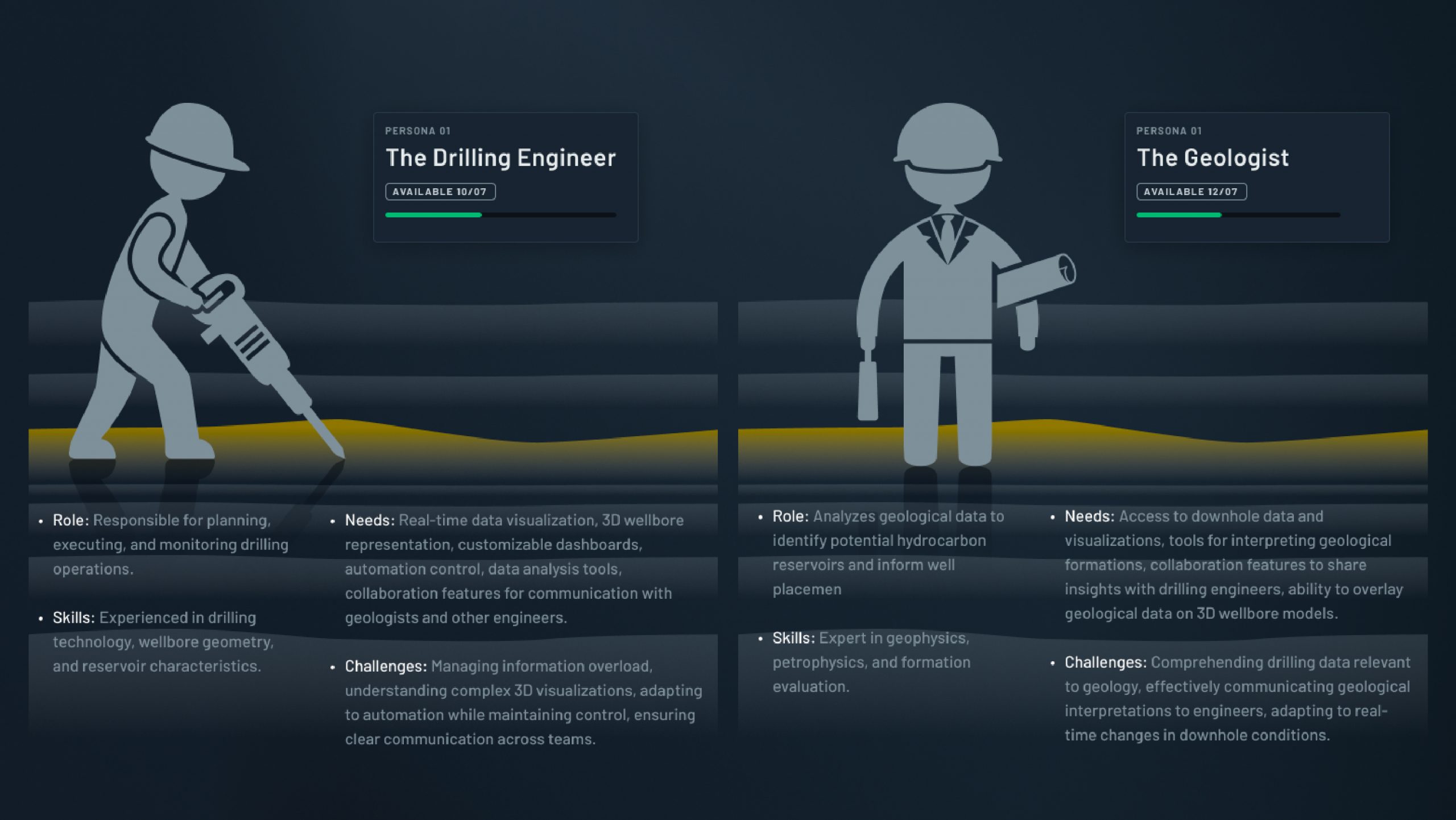

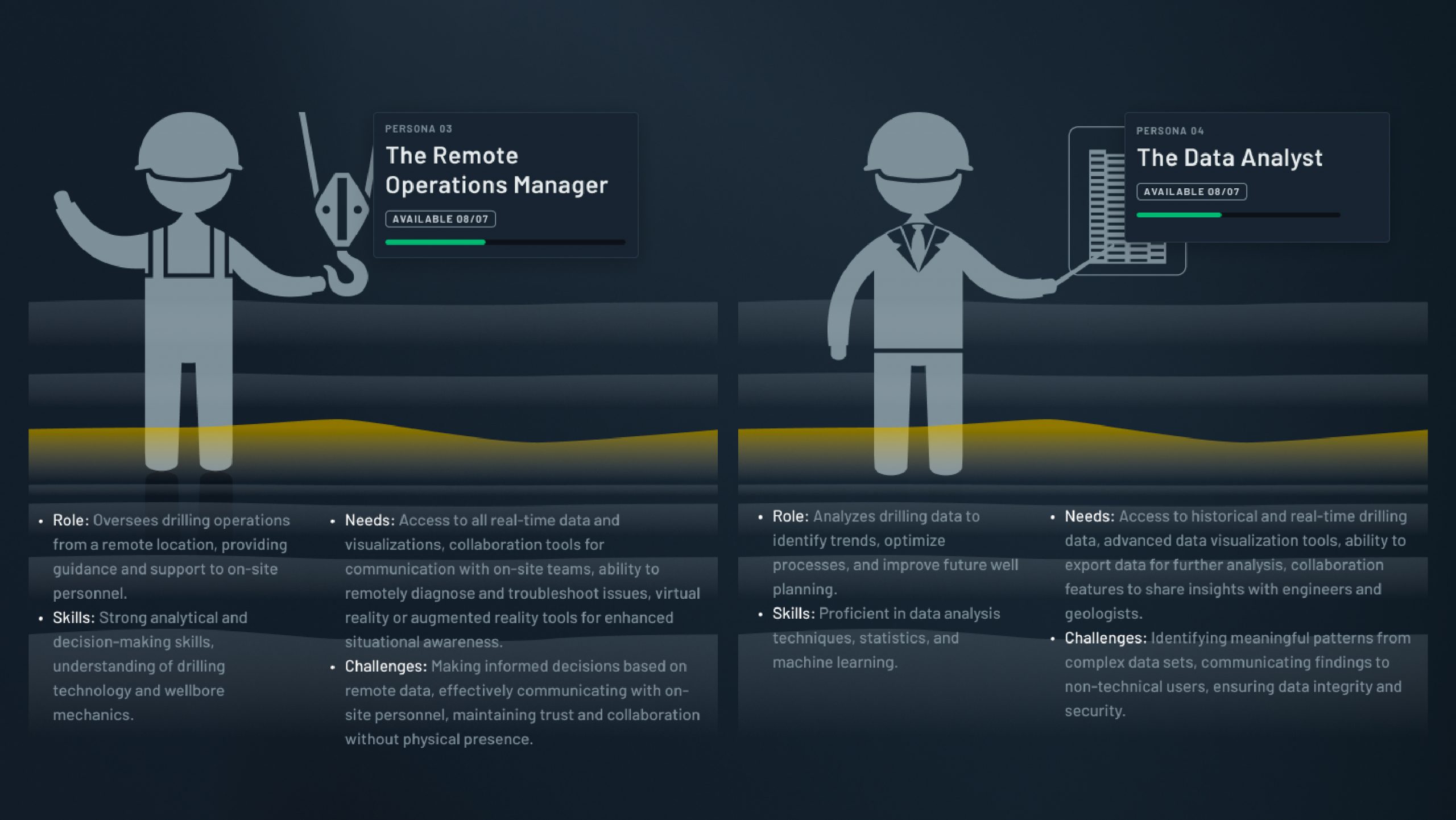

User personas

From this study, we could further segment our main user into five groups:The Drilling Engineer, The Geologist, The Drilling Supervisor, The Remote Operations Manager, The Data Analyst. We also broke down the users by their roles, skills, needs and challenges

Week 1

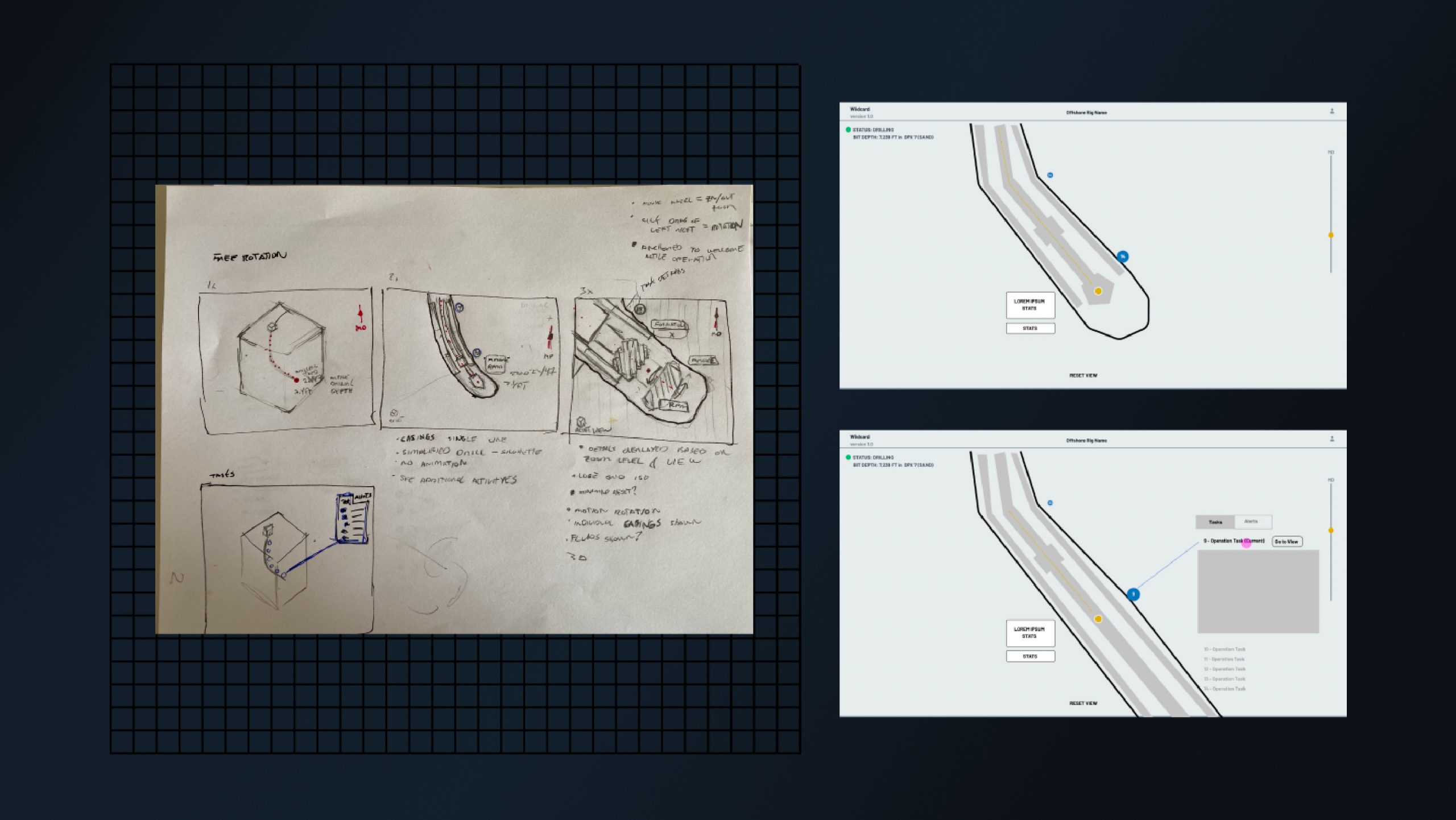

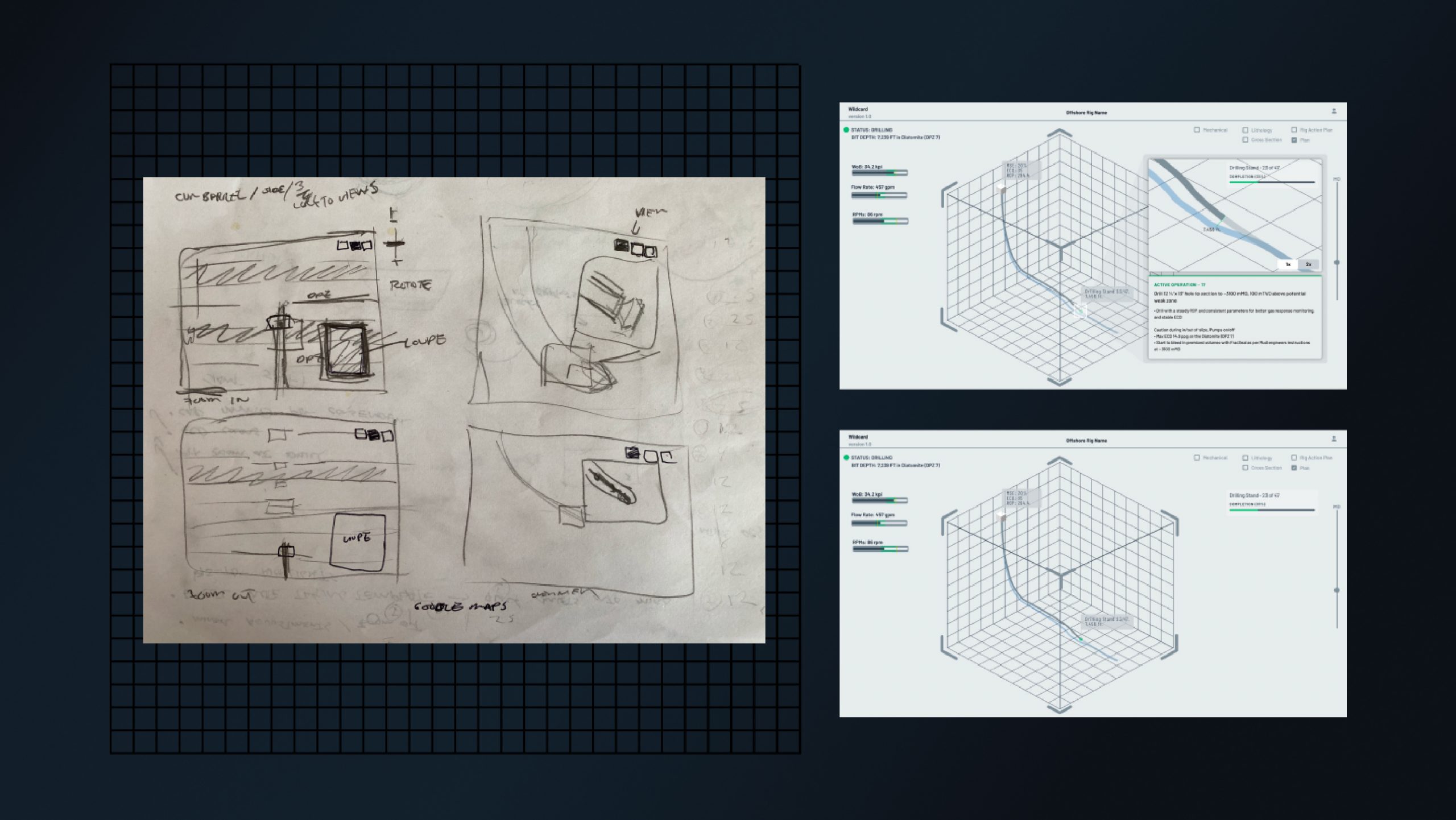

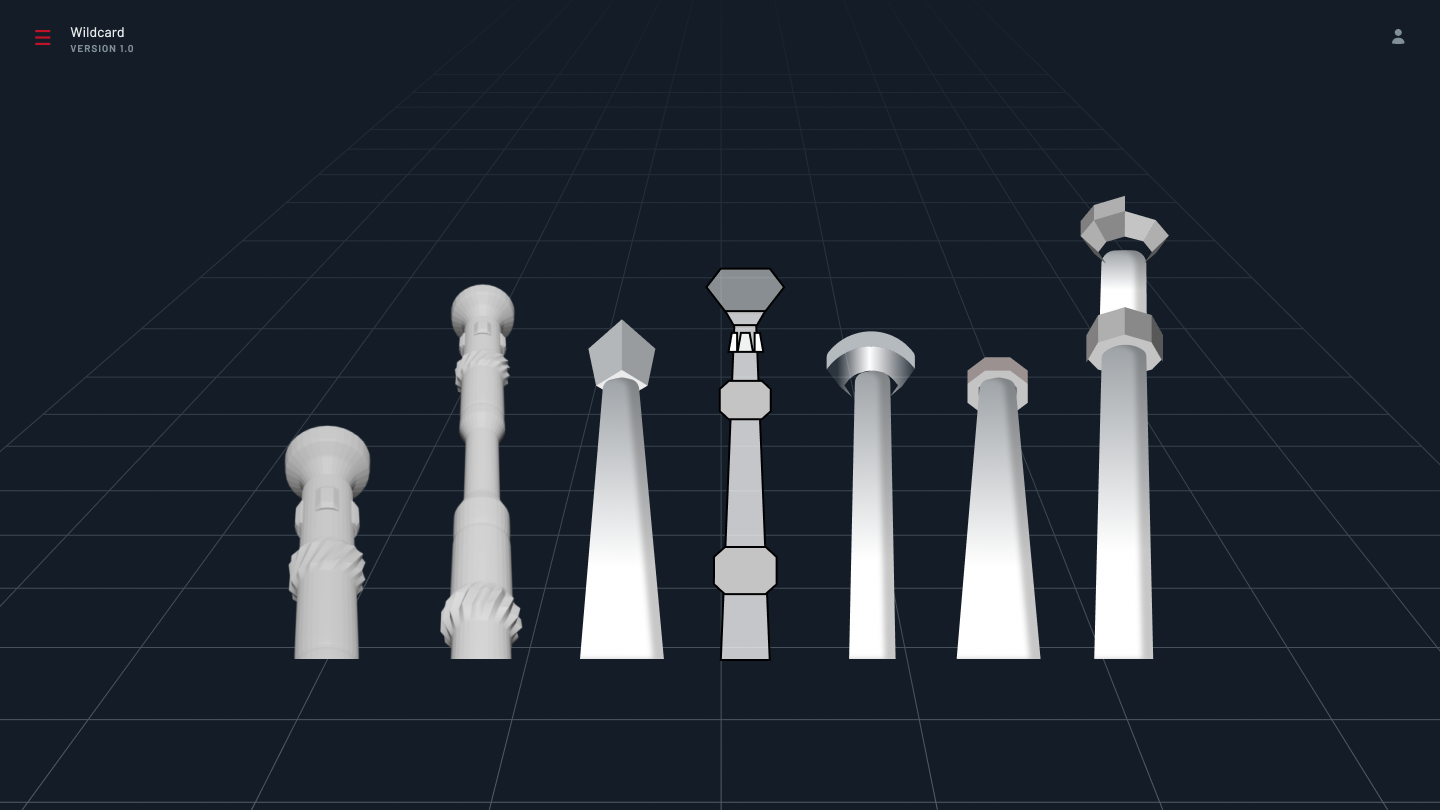

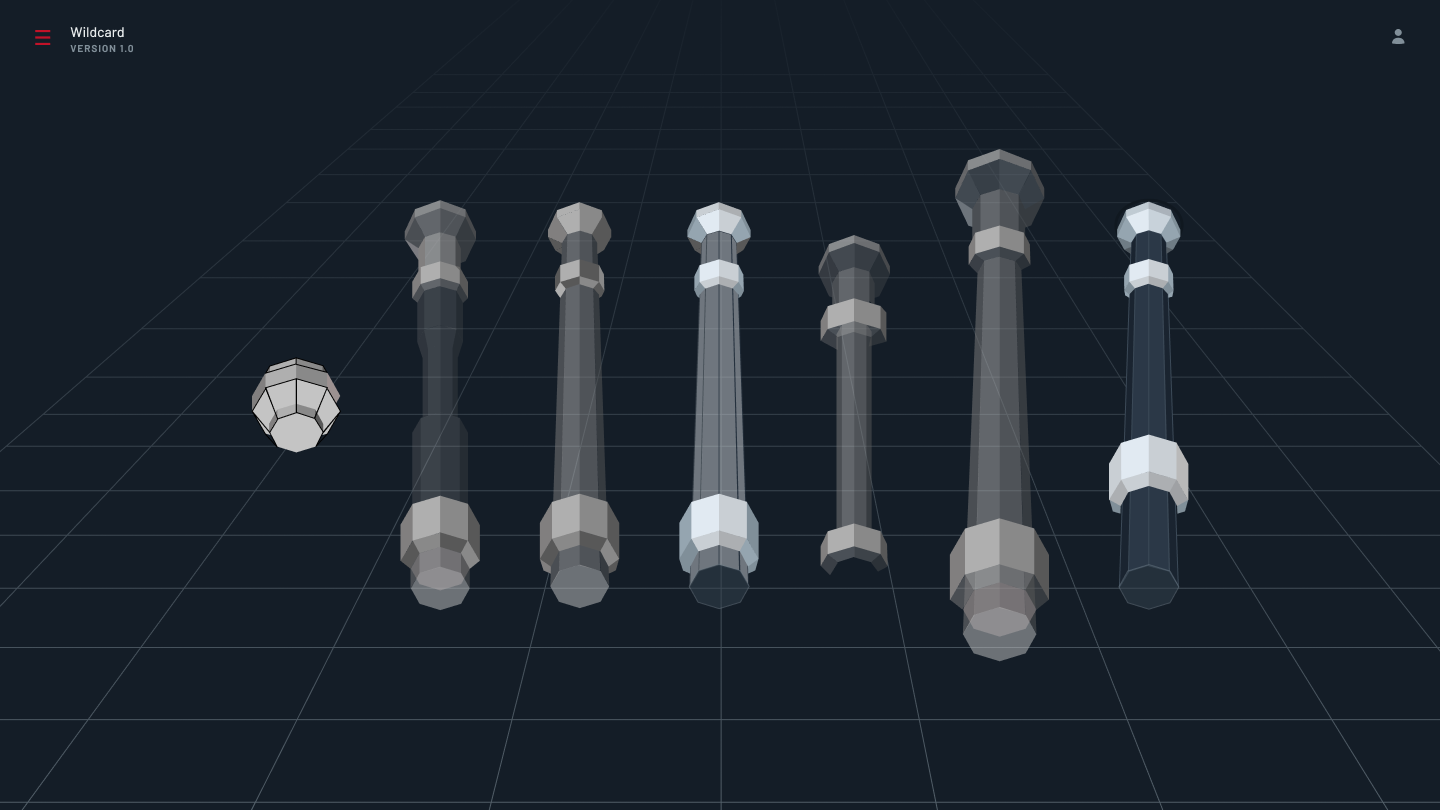

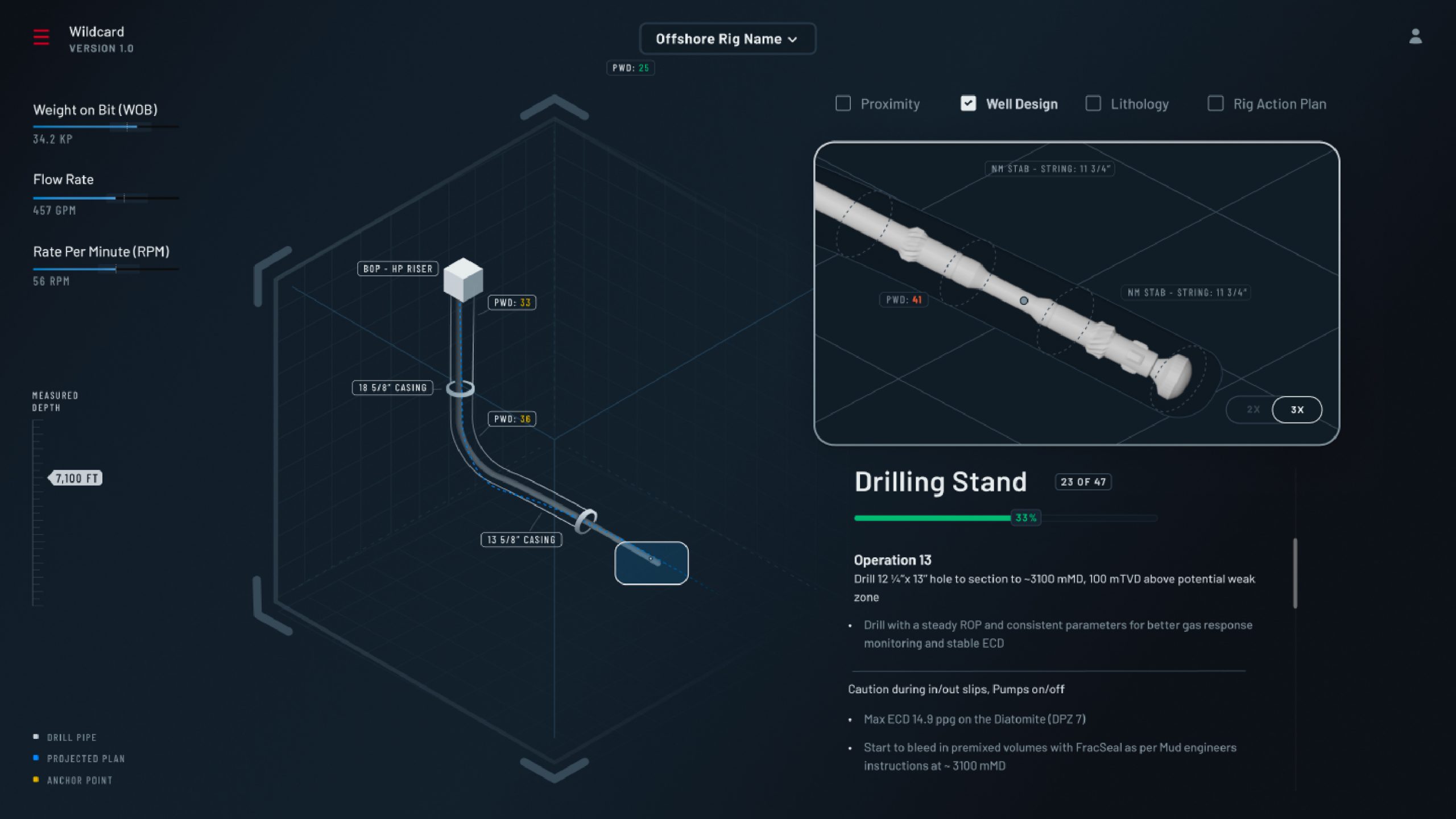

Initial Starting Visuals

Developing the initial models and components for Halliburton’s 3D Automated Drilling Solution Platform (3D ADSP) involves several crucial steps:

Step 1

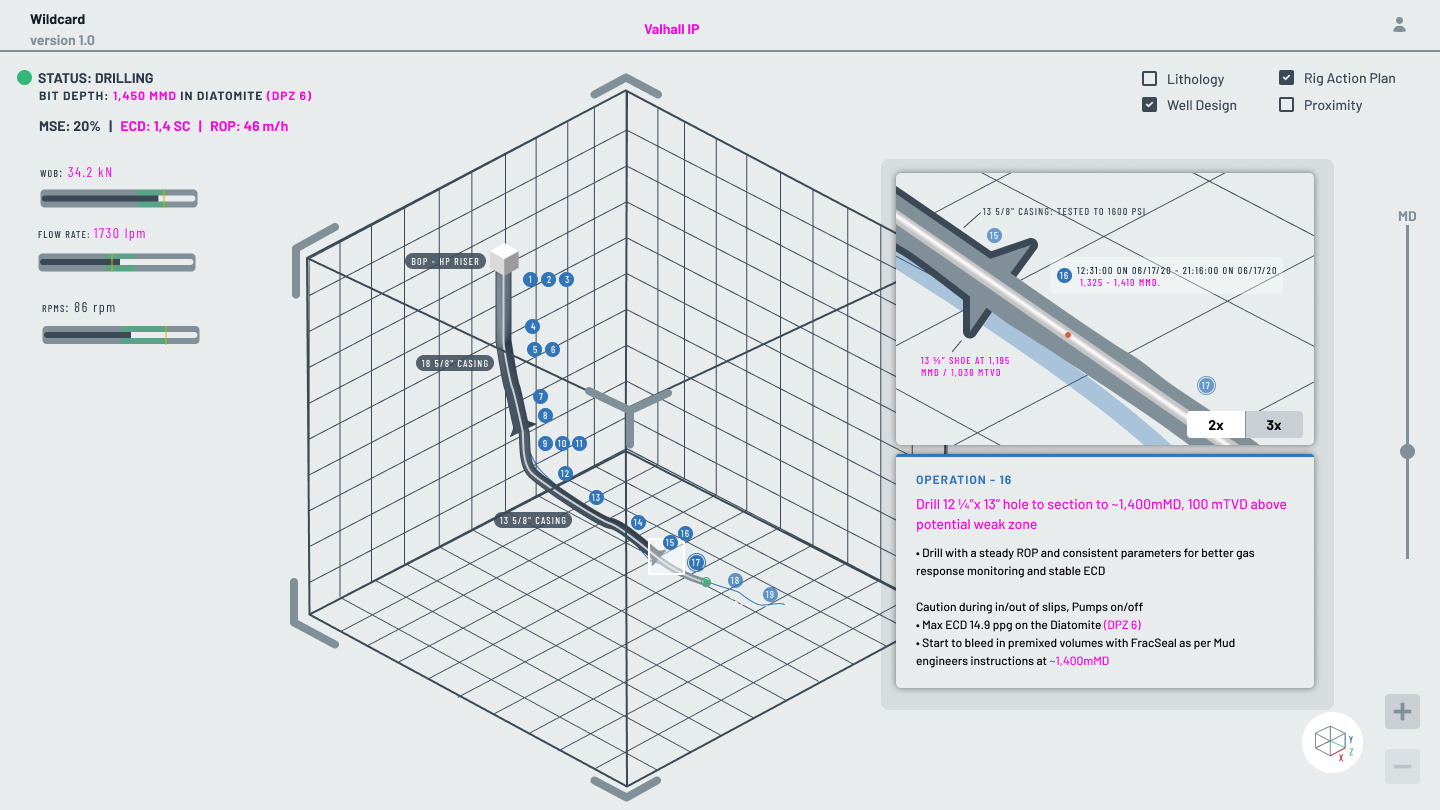

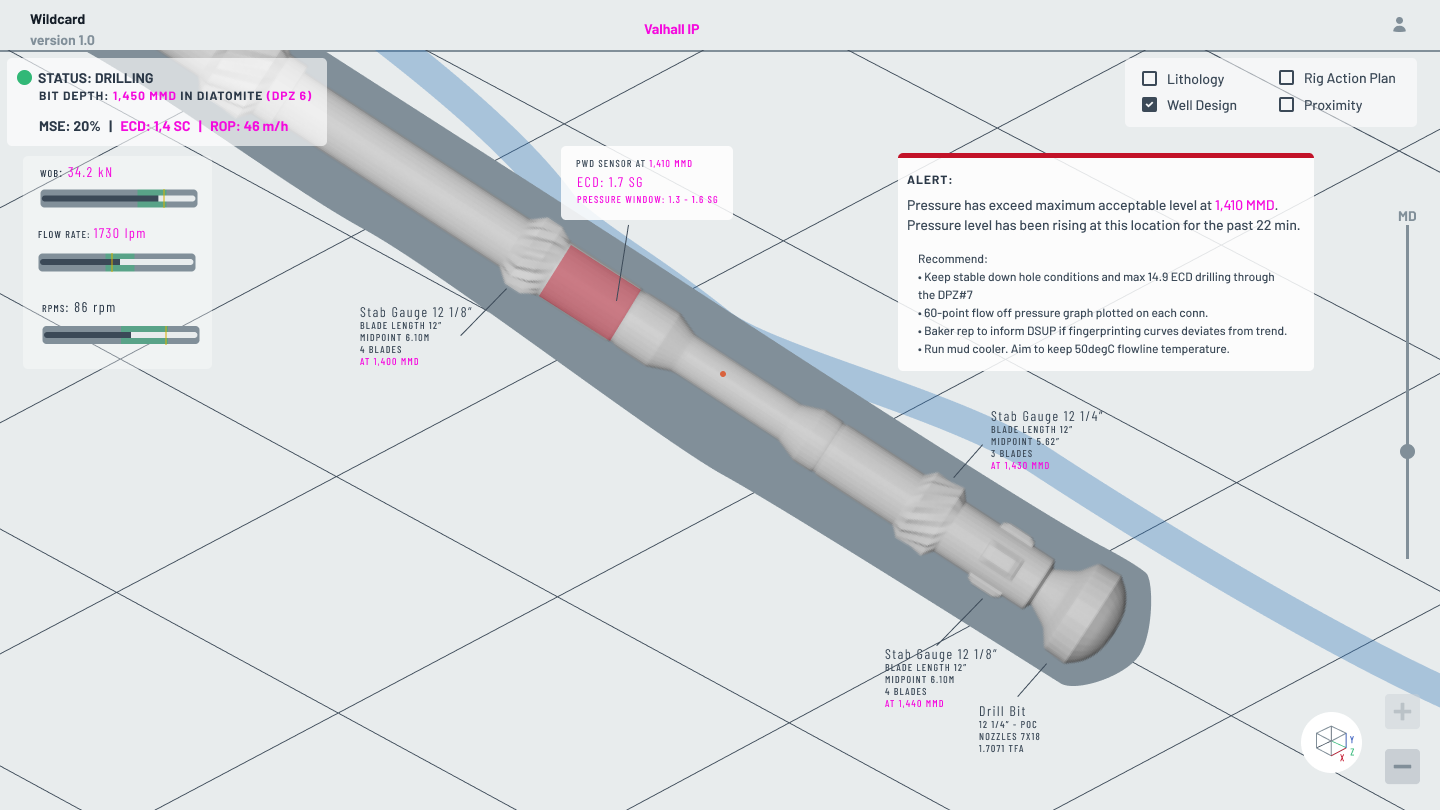

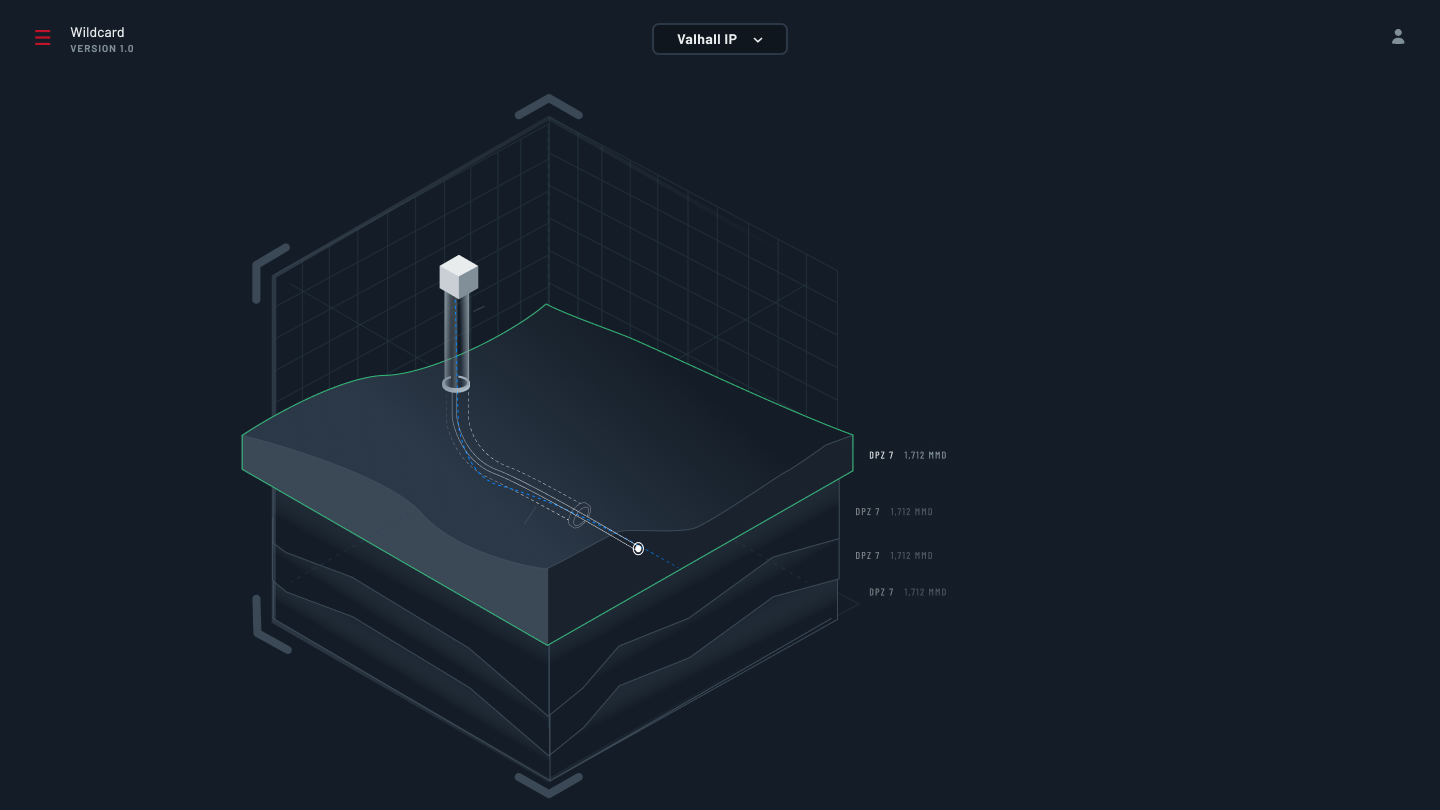

3D Wellbore Modeling and Visualization:

- Develop a 3D wellbore engine: Create a robust engine capable of generating and rendering accurate 3D models of wellbores in real-time. Consider using established libraries like OpenGL or Vulkan for efficient graphics rendering.

- Integrate real-time data: Integrate real-time data feeds from sensors and drilling processes into the 3D model, enabling dynamic visualization of wellbore progress, formation layers, and downhole conditions.

Step 2

Data Acquisition and Preparation:

- Gather real-world drilling data: Collect high-quality data from sensors, drilling logs, and historical records covering various well types, formations, and drilling conditions. This data serves as the foundation for model training and validation.

- Data pre-processing and cleaning: Clean and pre-process the collected data to address missing values, outliers, and inconsistencies. Ensure data standardization for compatibility with chosen modeling tools and algorithms.

Week 2

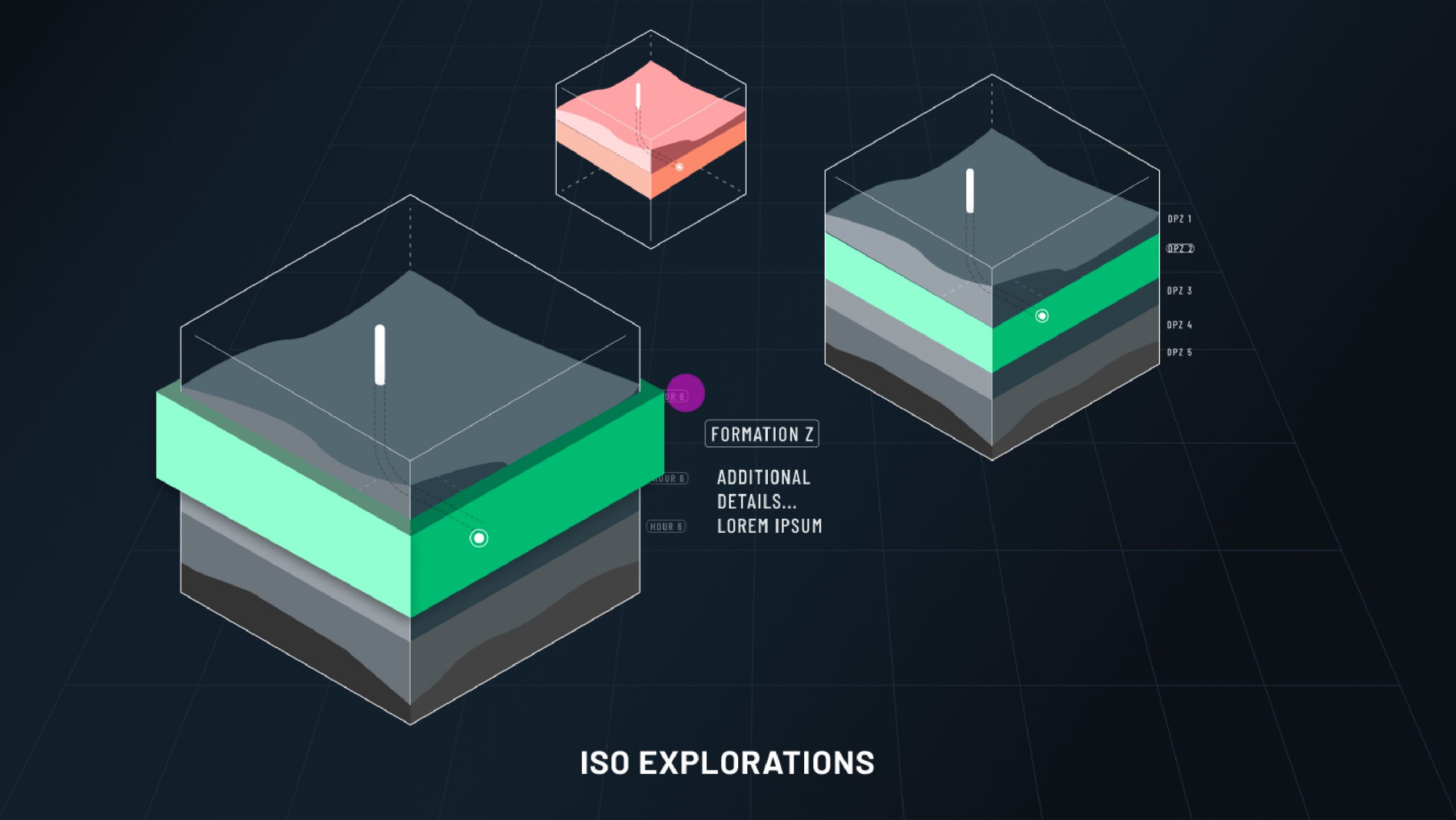

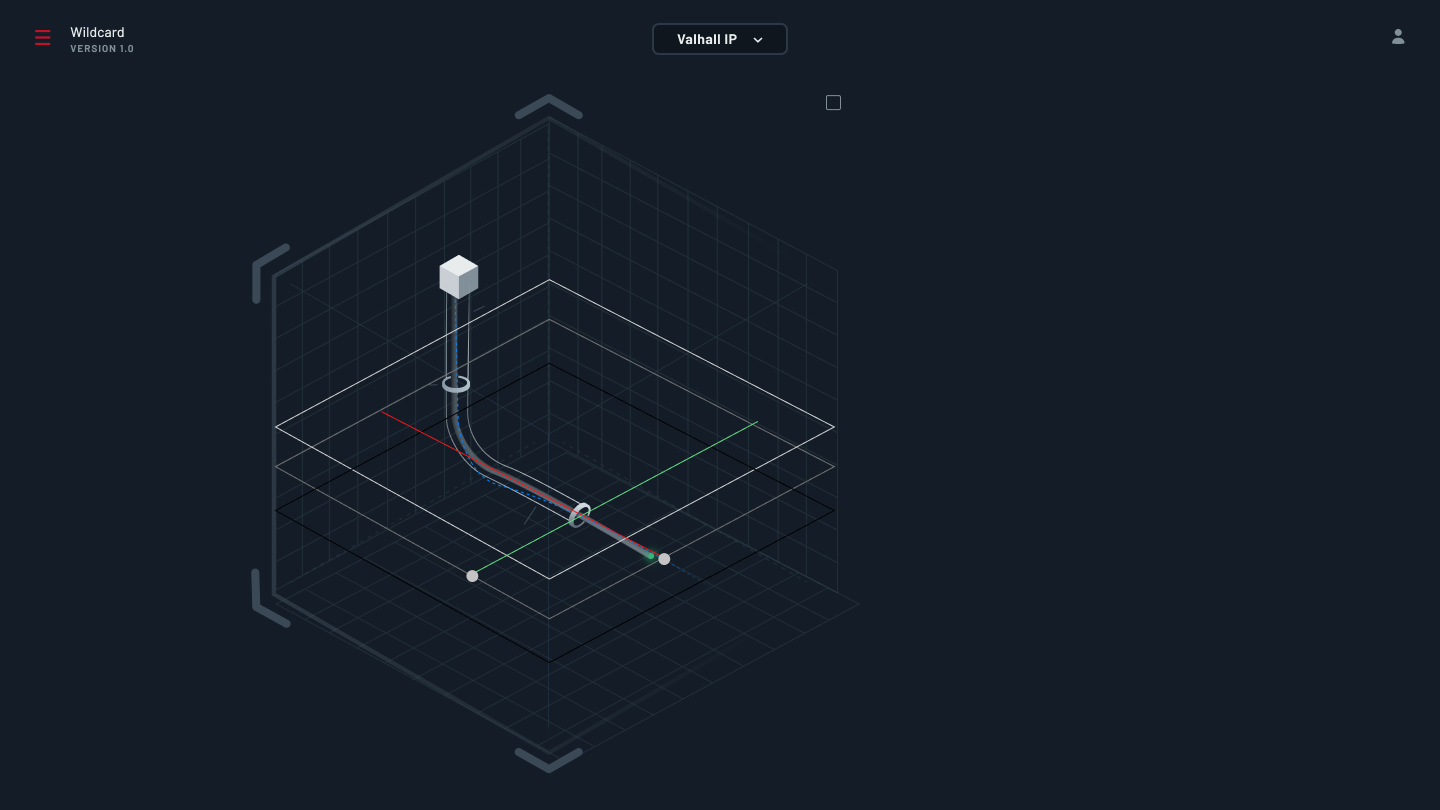

Approaching 3D Model Design

- What level of detail is necessary? Balance detail with performance and clarity. Excessive detail can overwhelm users, while insufficient detail may limit their understanding.

- Data integration: Determine how real-time and historical data will be streamed into the 3D model and visualized effectively. Consider using established data visualization libraries like Matplotlib or Plotly for enhanced visual representation.

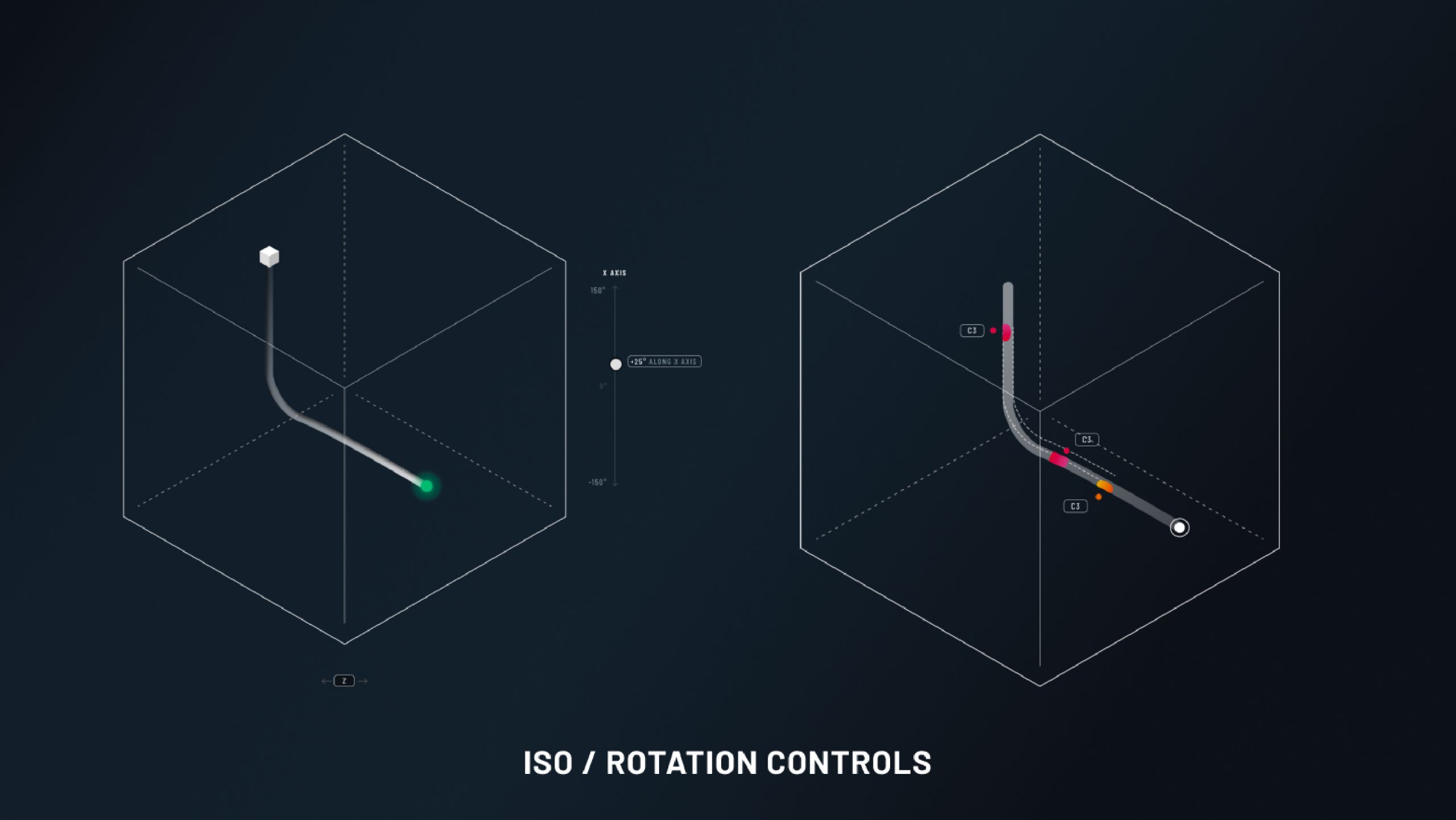

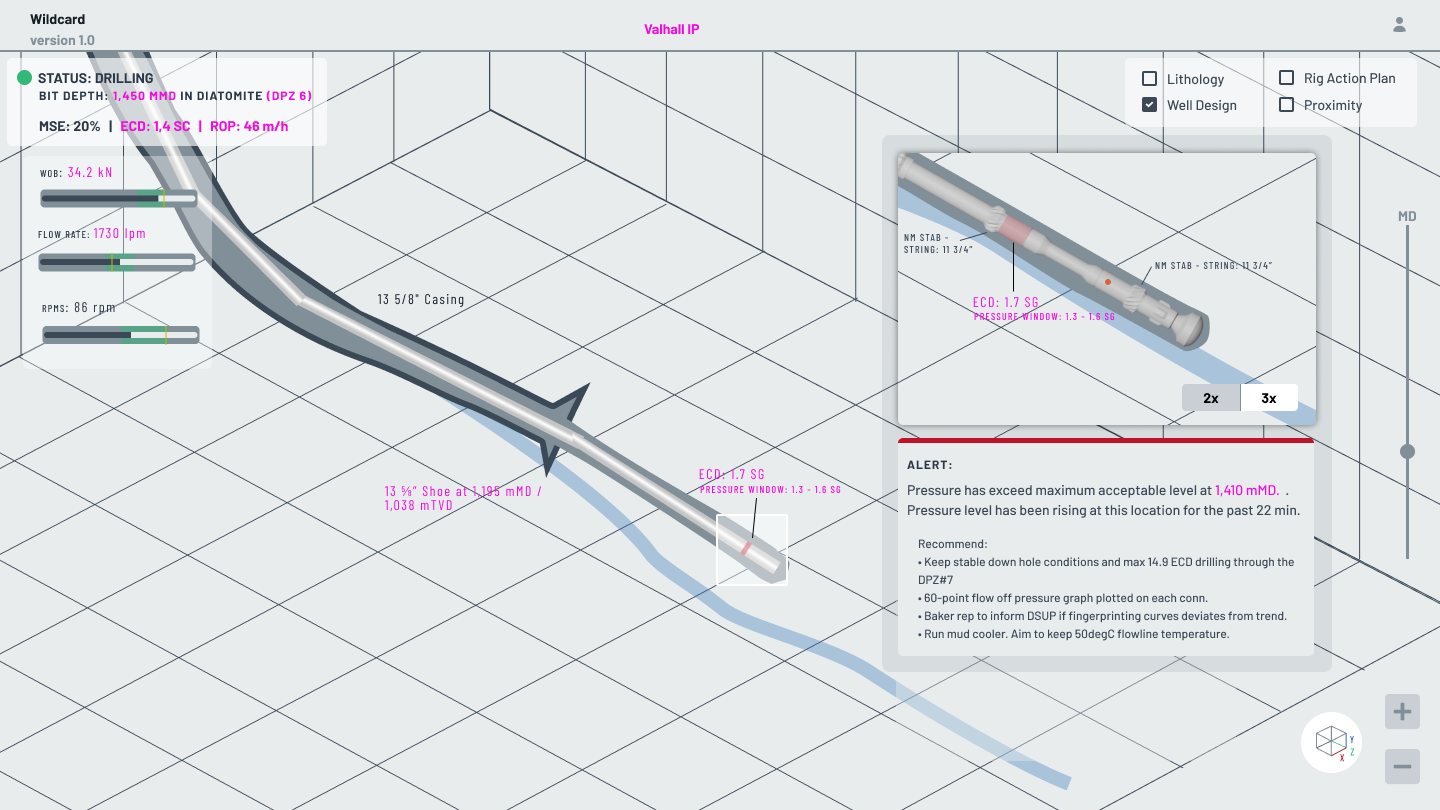

- Level of interactivity: Decide what level of interaction users should have with the 3D model. This could include zooming, rotating, highlighting specific elements, and overlaying data charts.

- Focus on clarity and legibility: Prioritize clear visuals and intuitive data representation. Use color, size, and transparency effectively to differentiate elements and avoid cognitive overload

week 3

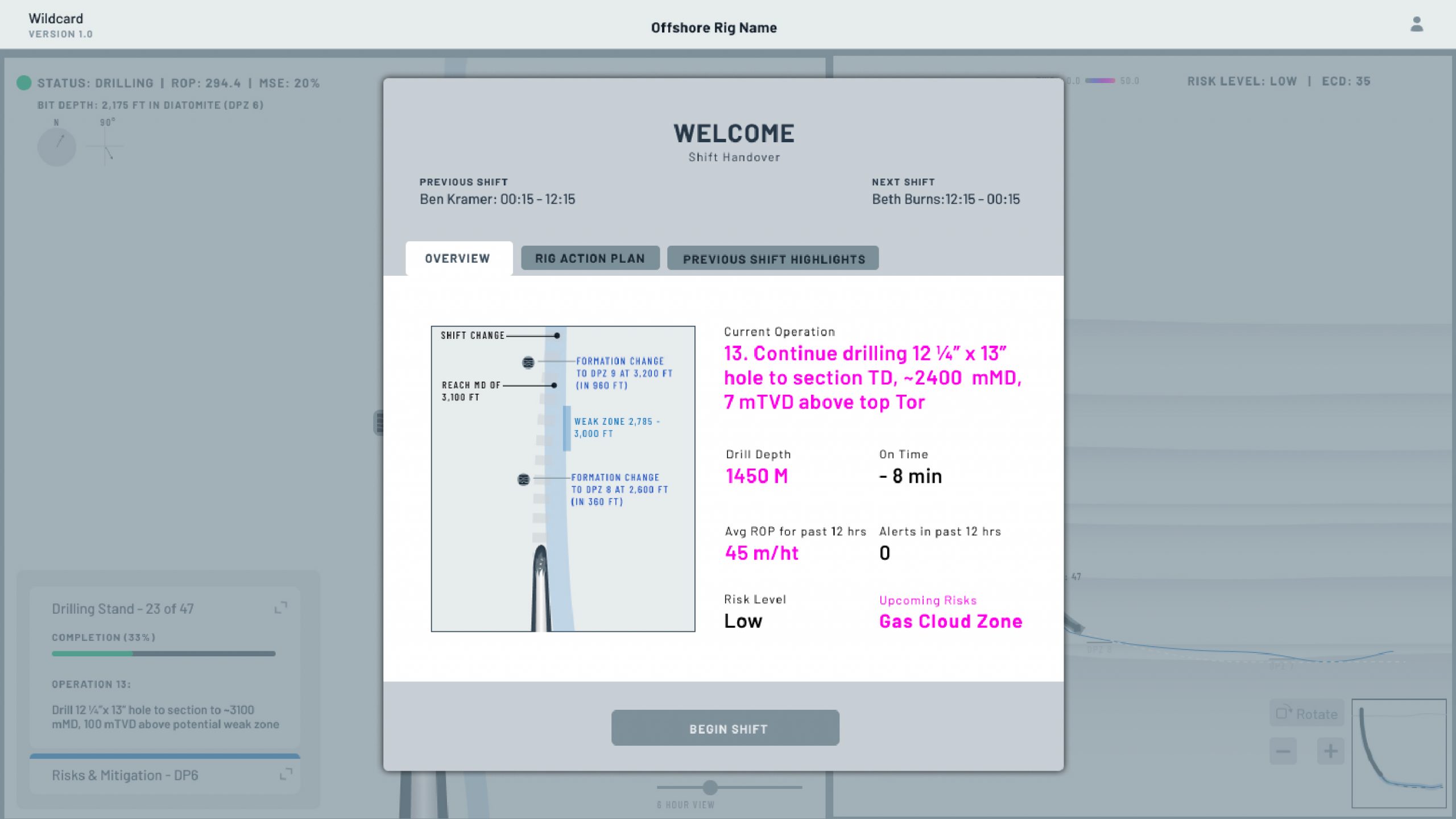

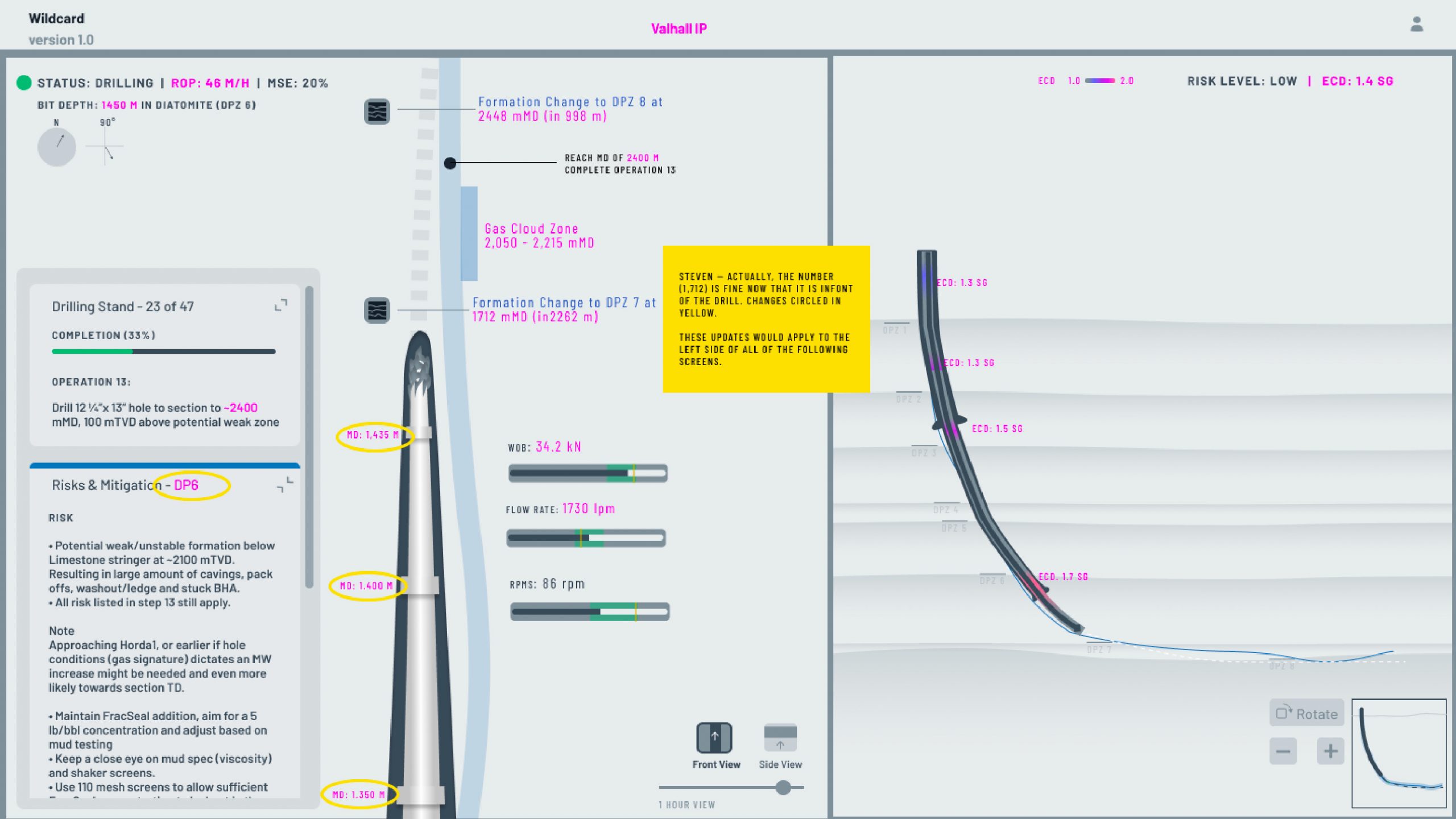

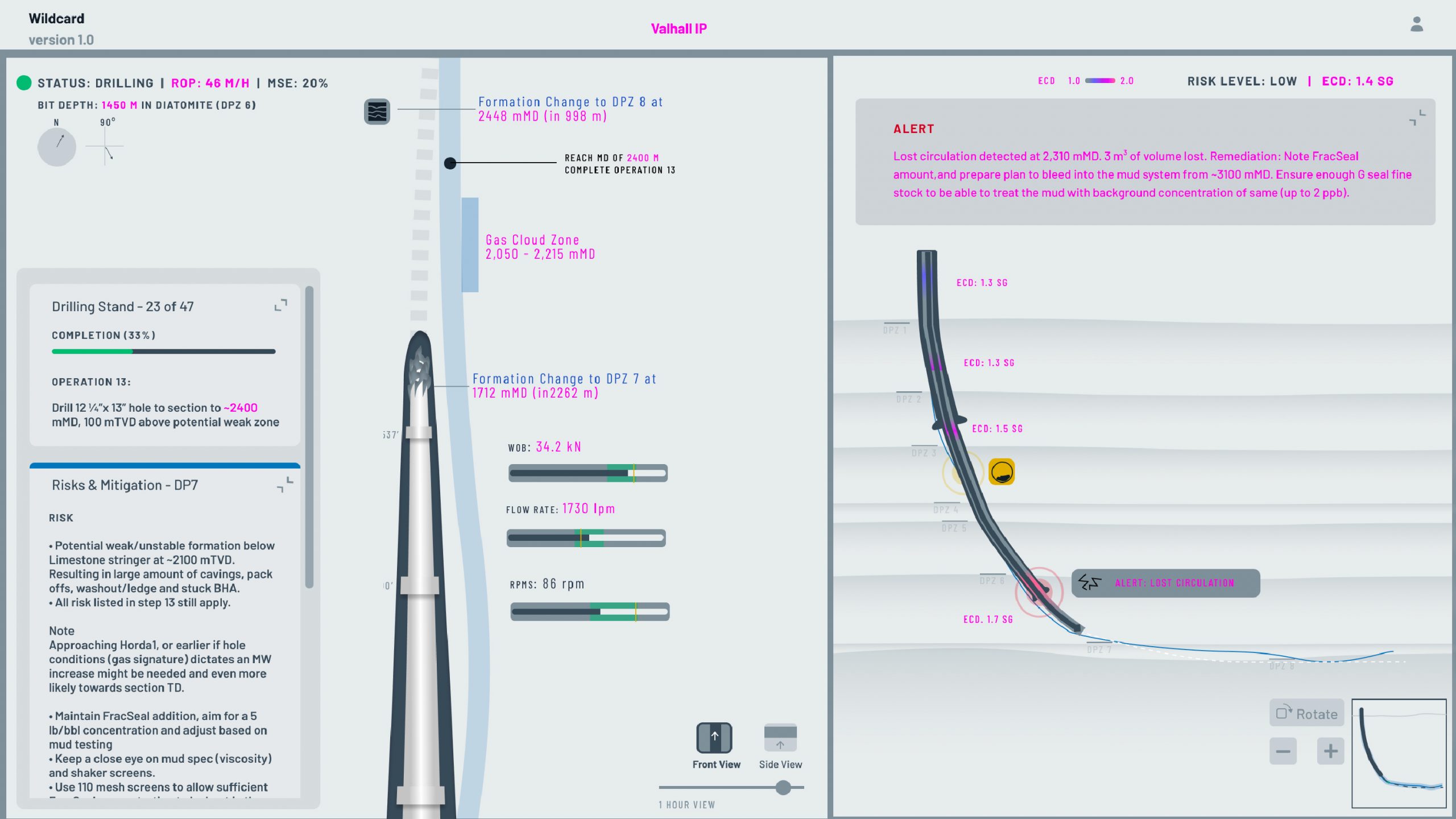

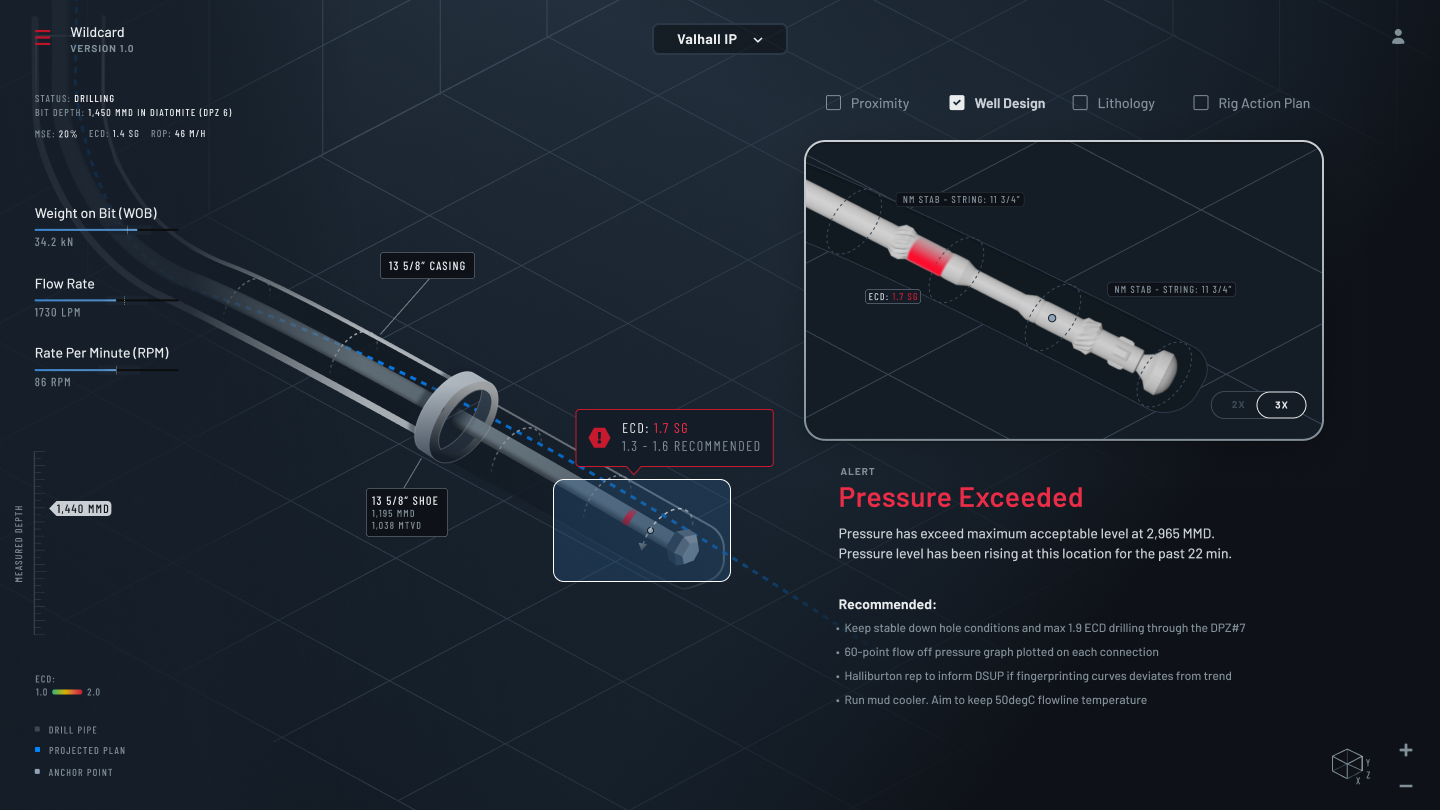

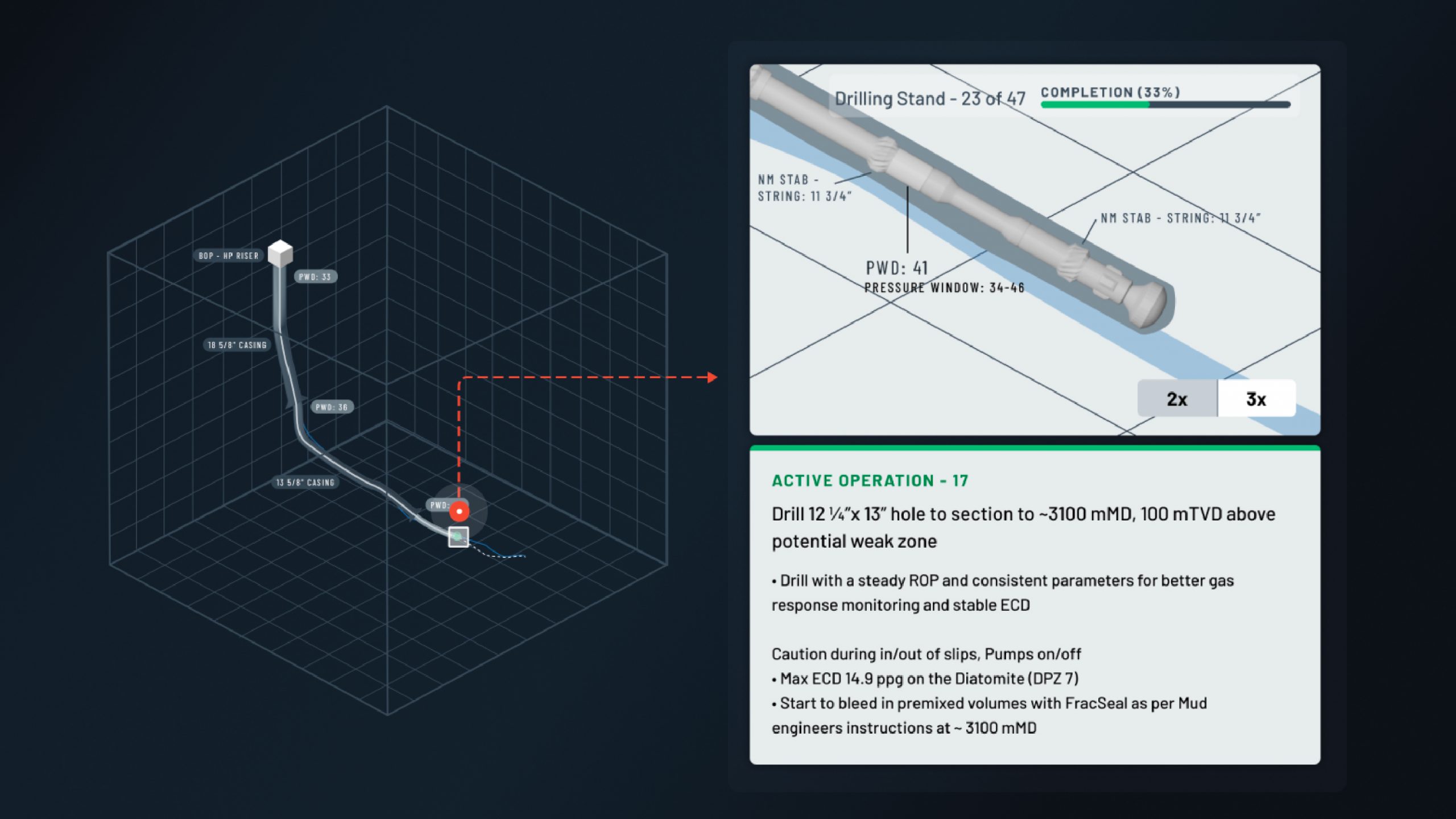

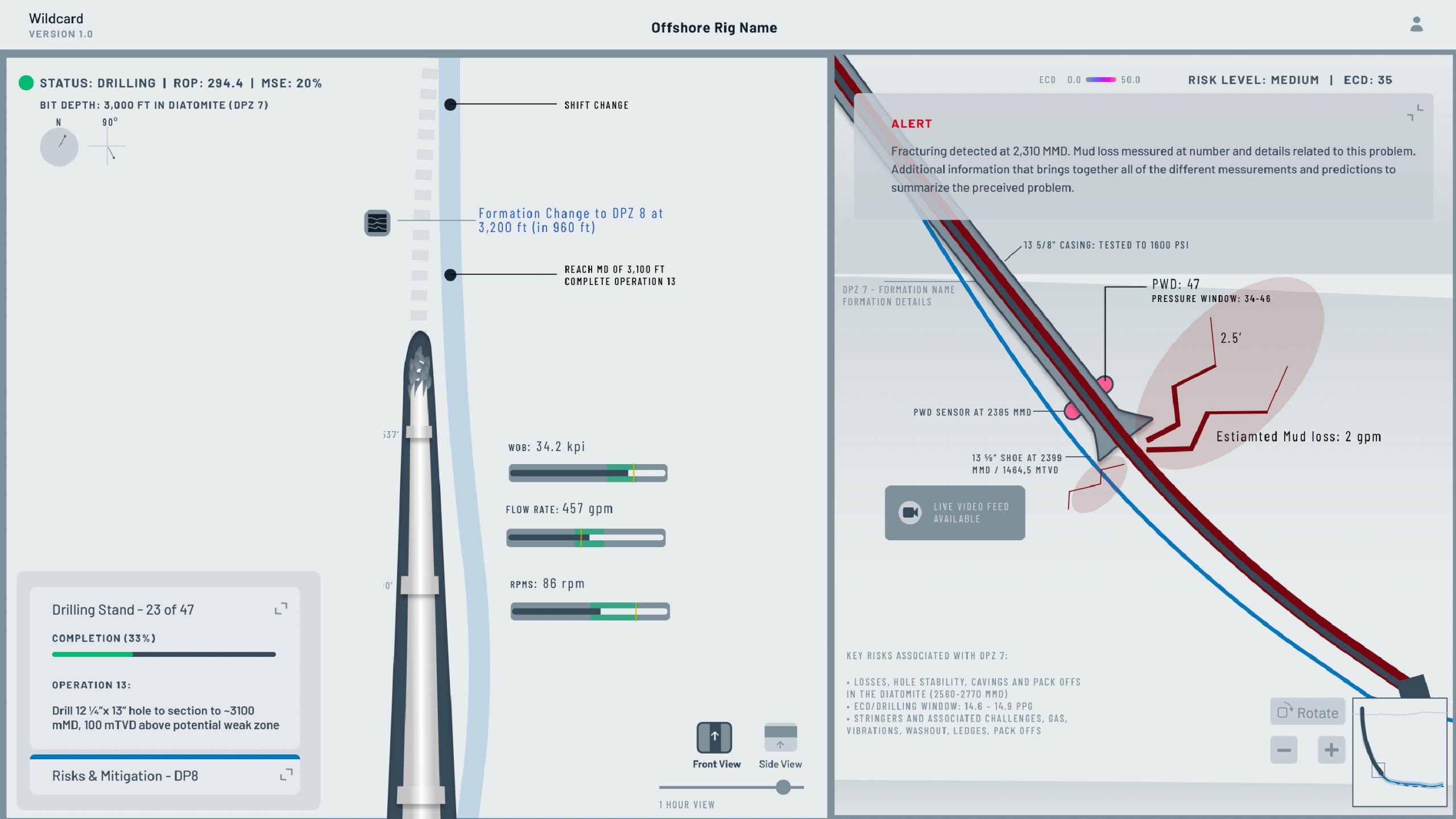

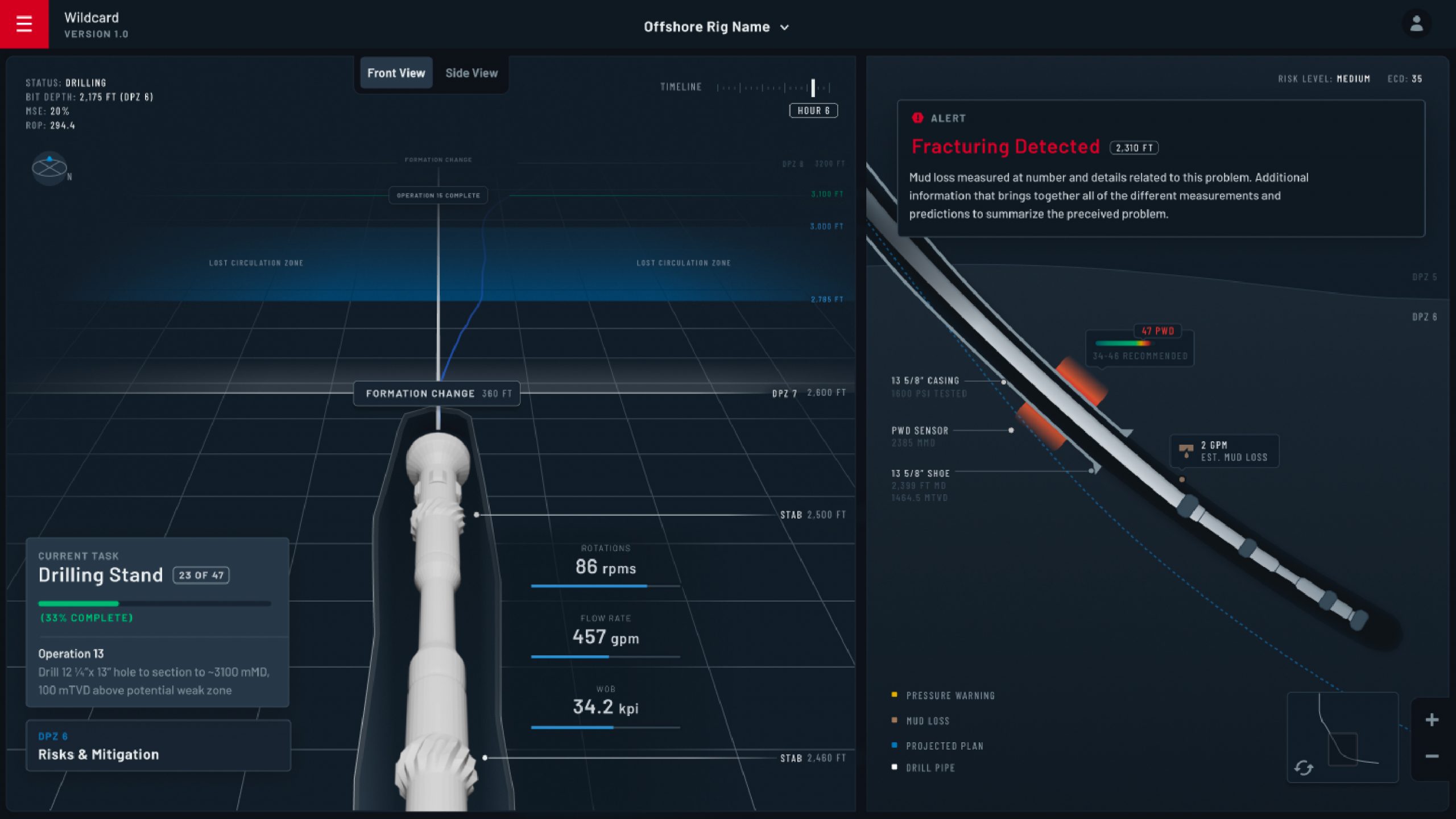

Rig Action Plan

Fracturing detected at 2,310 MMD. Mud loss messured at number and details related to this problem. Additional information that brings together all of the different messurements and predictions to summarize the preceived problem.

week 4 - 5

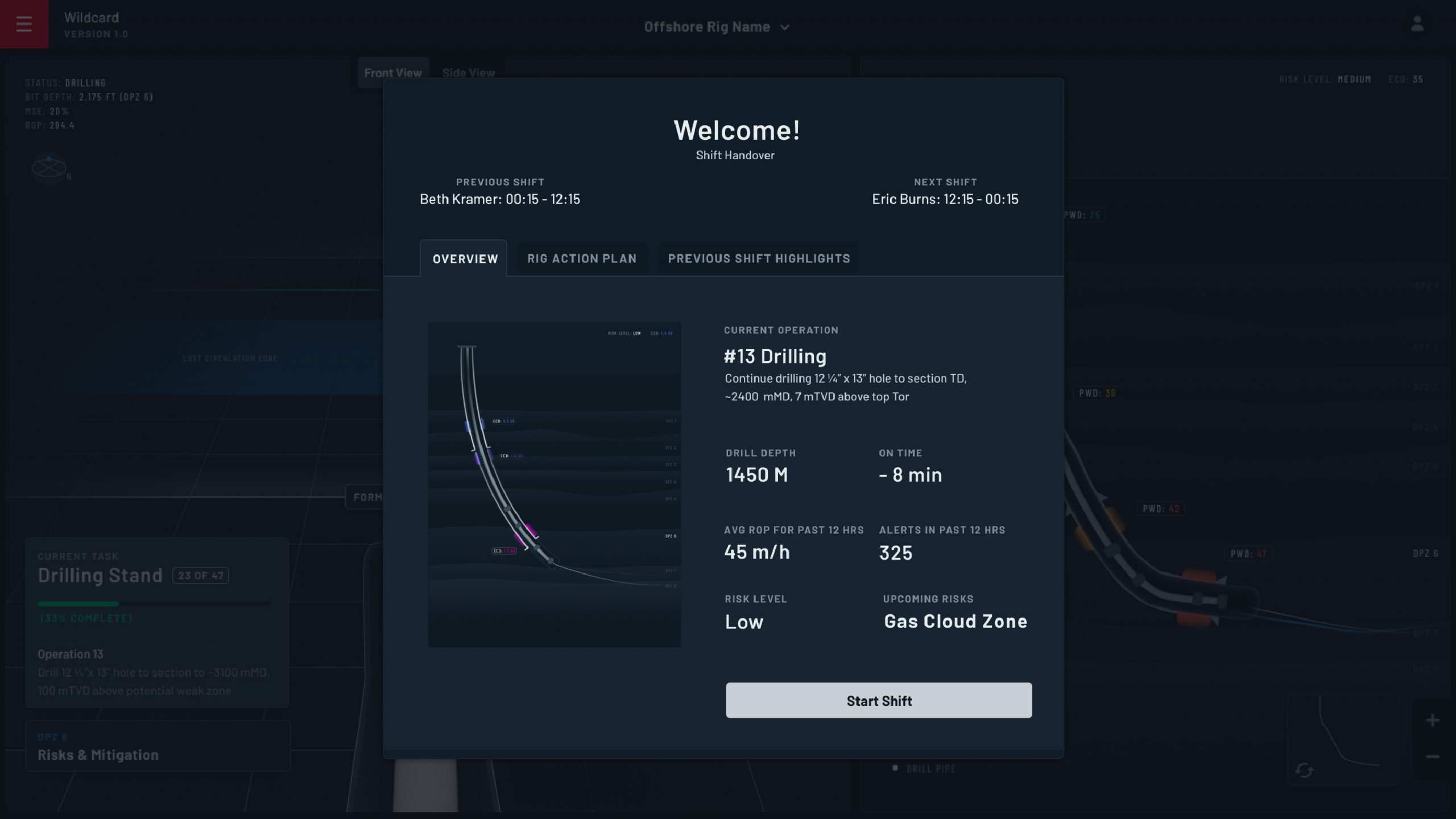

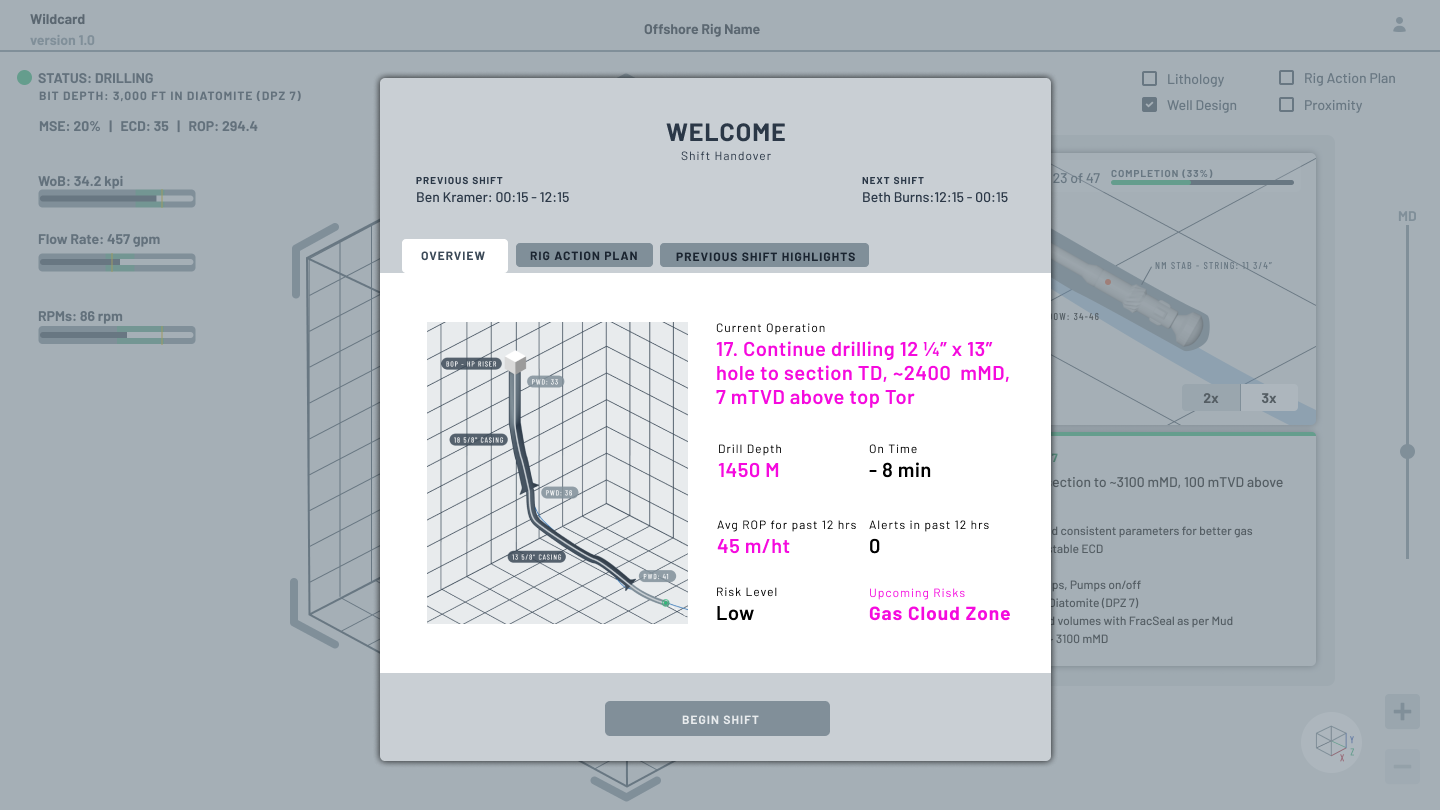

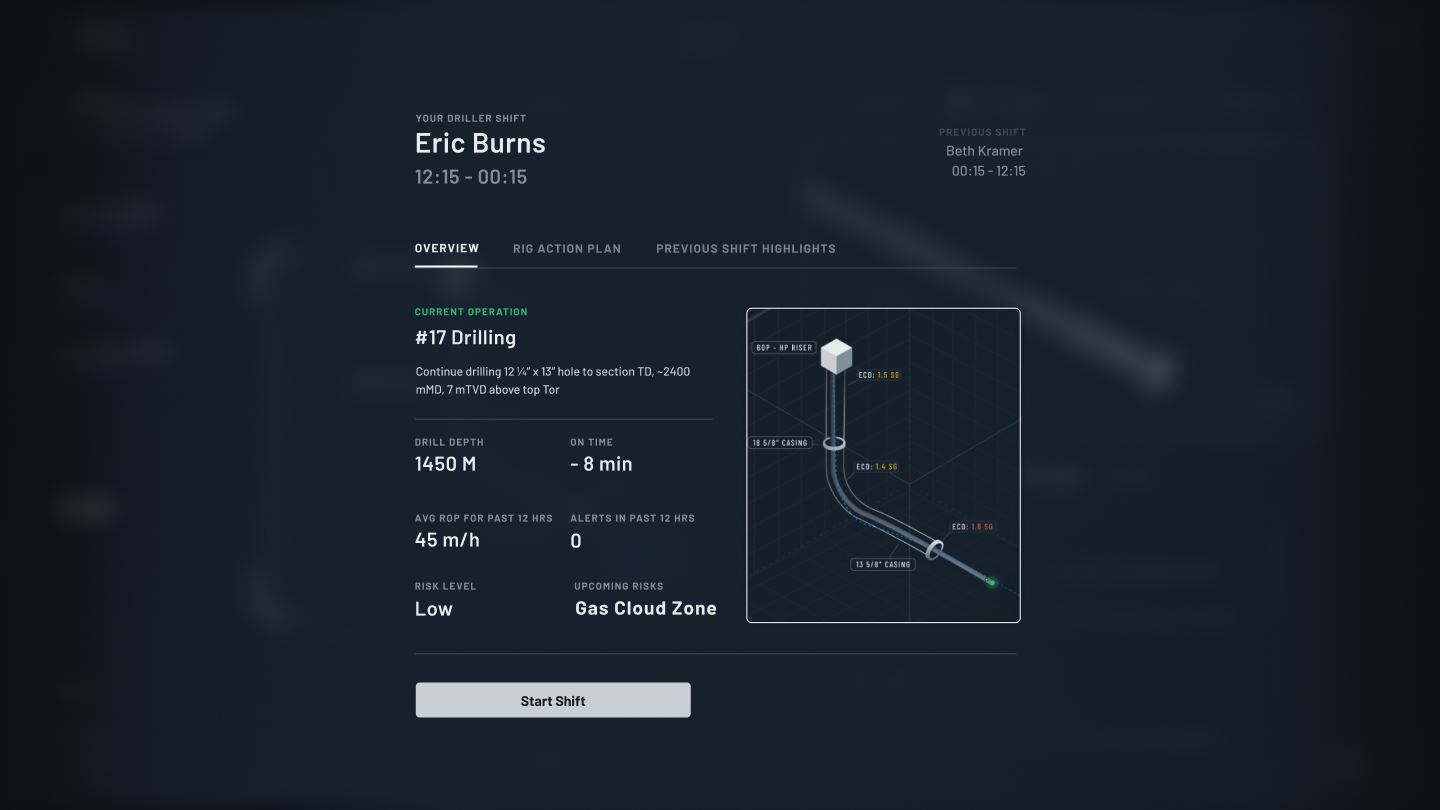

Shift handover process flow

Based on our user interviews, we identified some key issues to be aware of:

• Did not clearly define responsibilities and information needs.

• Did not provide written guidance.

• Did not mention it in their safety case.

• Lacked risk awareness among their operators.

• Provided little or no training.

• Did little monitoring or auditing.

• Had accidents that involved miscommunication at shift handover, e.g., maintenance or plant status.

week 6

Shift handover process flow

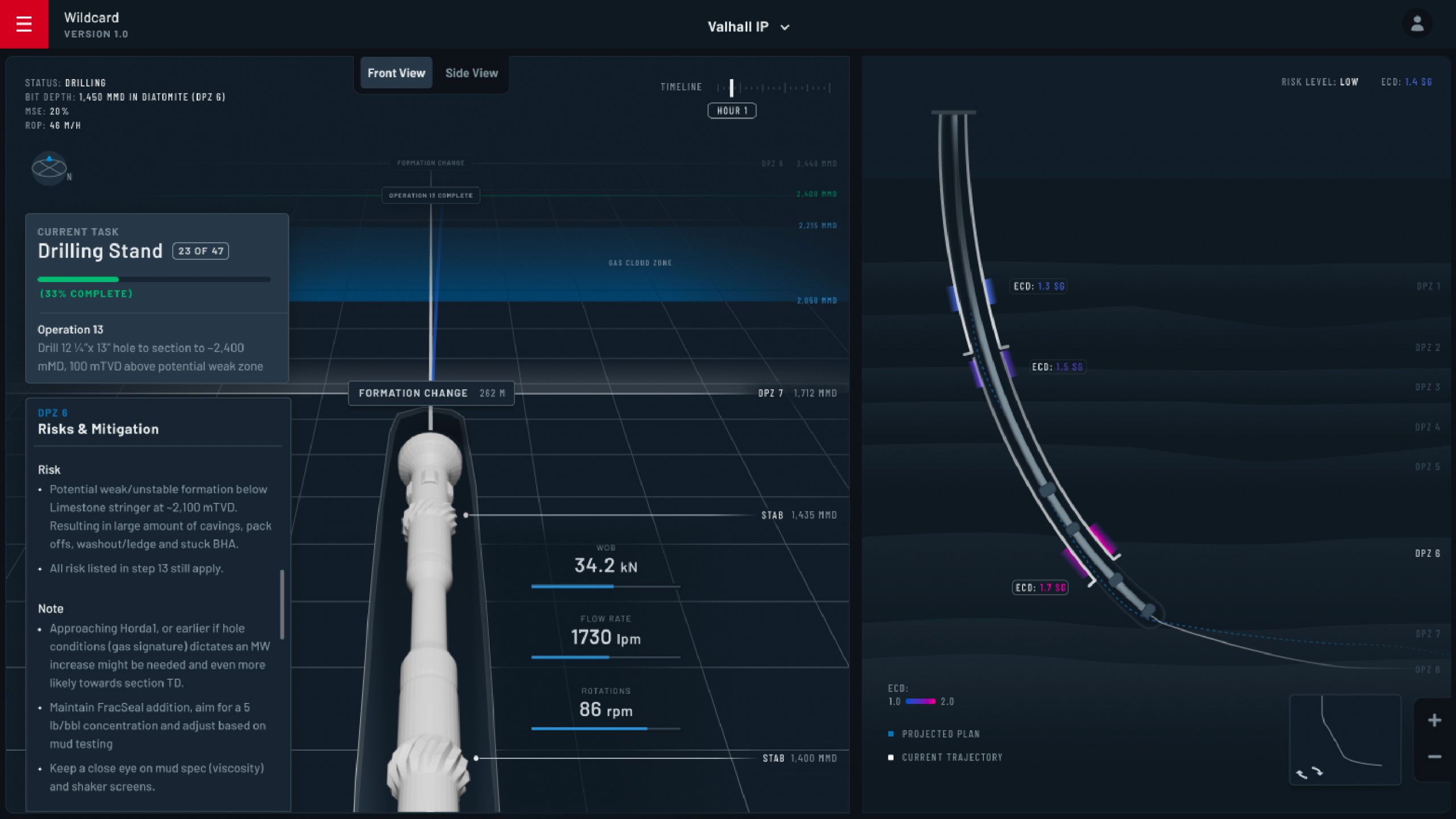

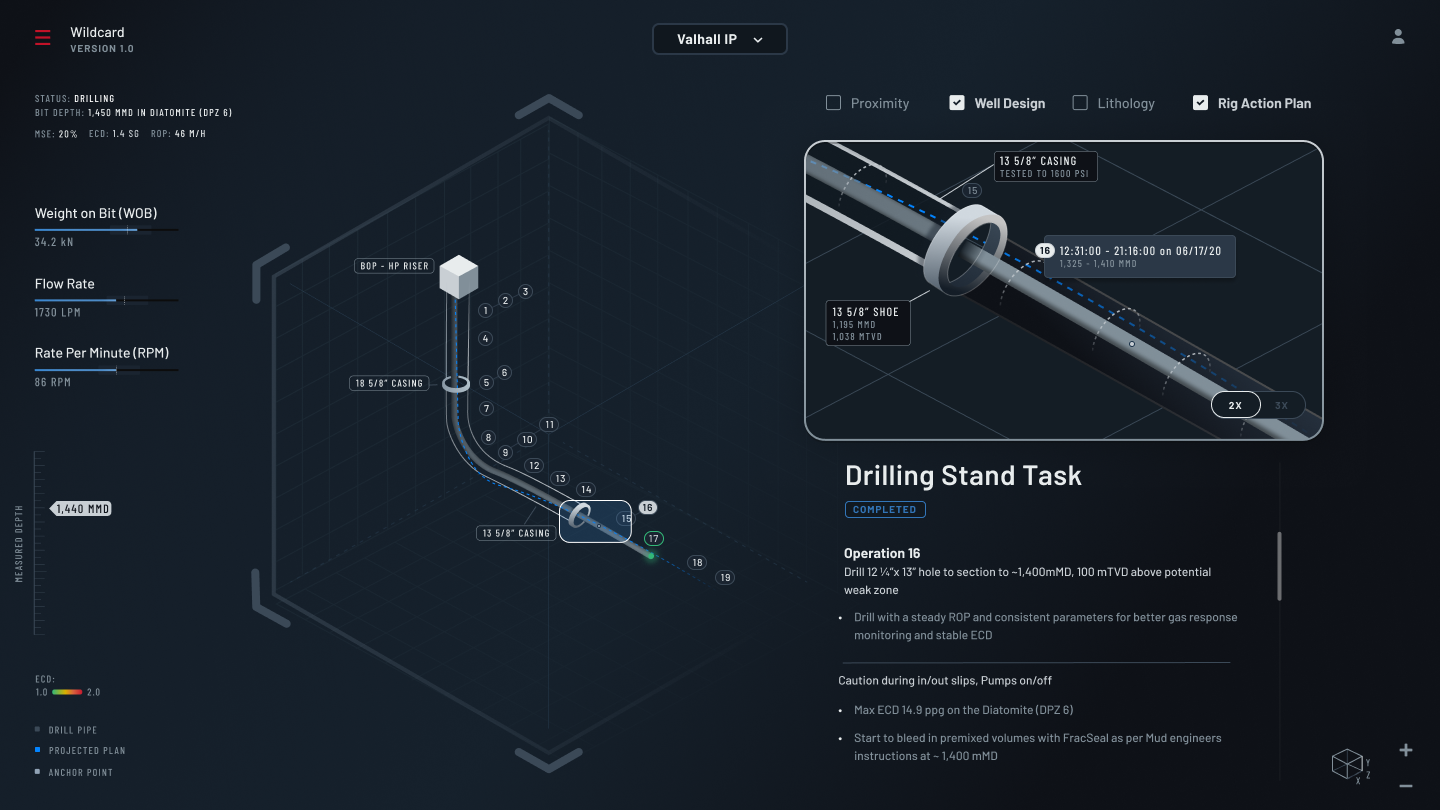

Initial the view of Isometric Loupe by gathering information from the split view before.

week 7

Optimize Models and Integration

- Strike a balance: Reduce model complexity where possible without compromising visual clarity or essential information.

- Apply level-of-detail (LOD) techniques: Dynamically adjust model detail based on viewing distance and user interaction to optimize performance.

- Consider geometric simplification: Reduce polygon count and simplify shapes for less visually critical elements.

- Utilize texture optimization: Employ appropriate texture compression formats and sizes for efficient rendering.

- Explore procedural techniques: Generate details like textures or geometry procedurally when required, reducing model size and memory usage.

week 8-9-10

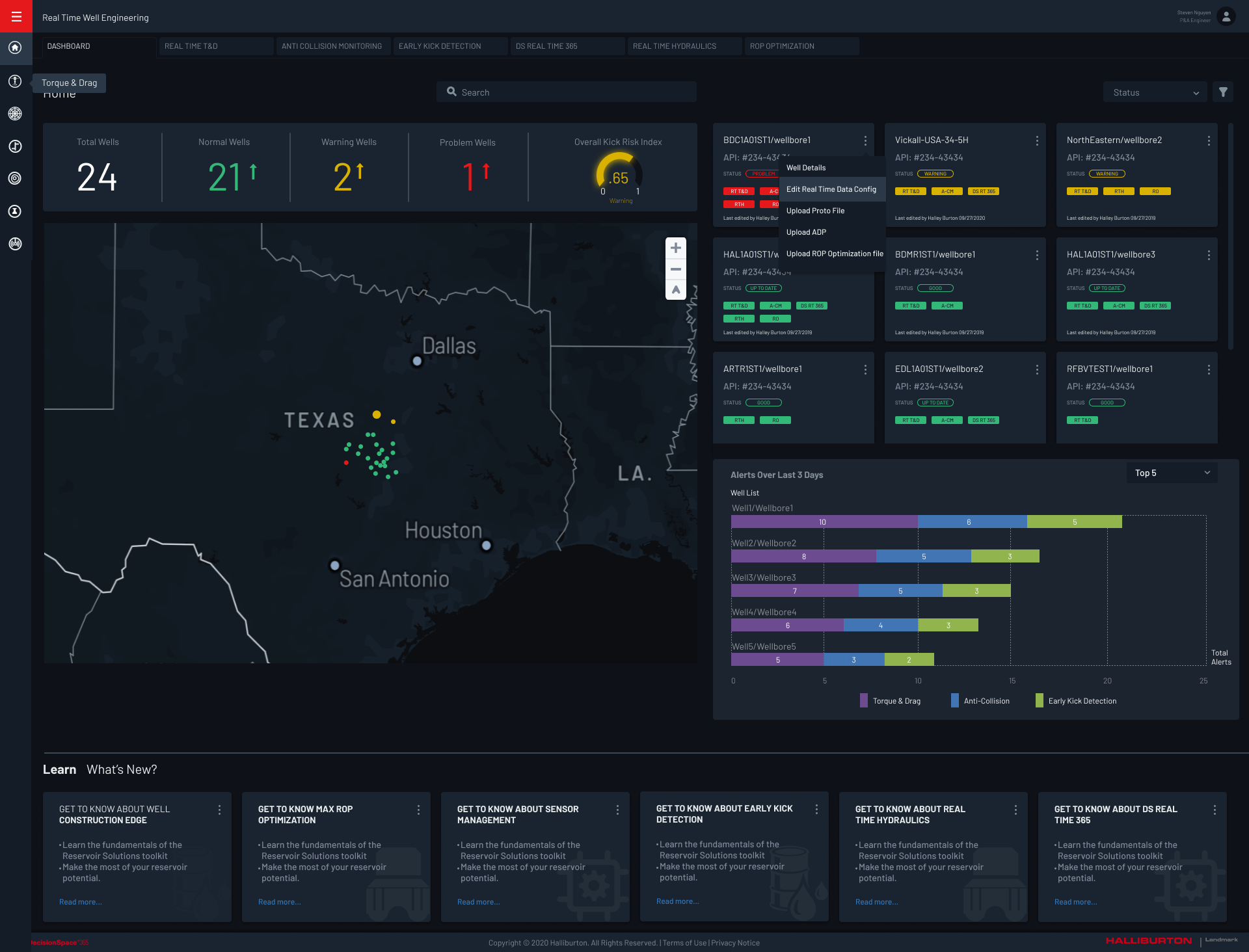

Comprehensive approach to design Dashboard

-

-

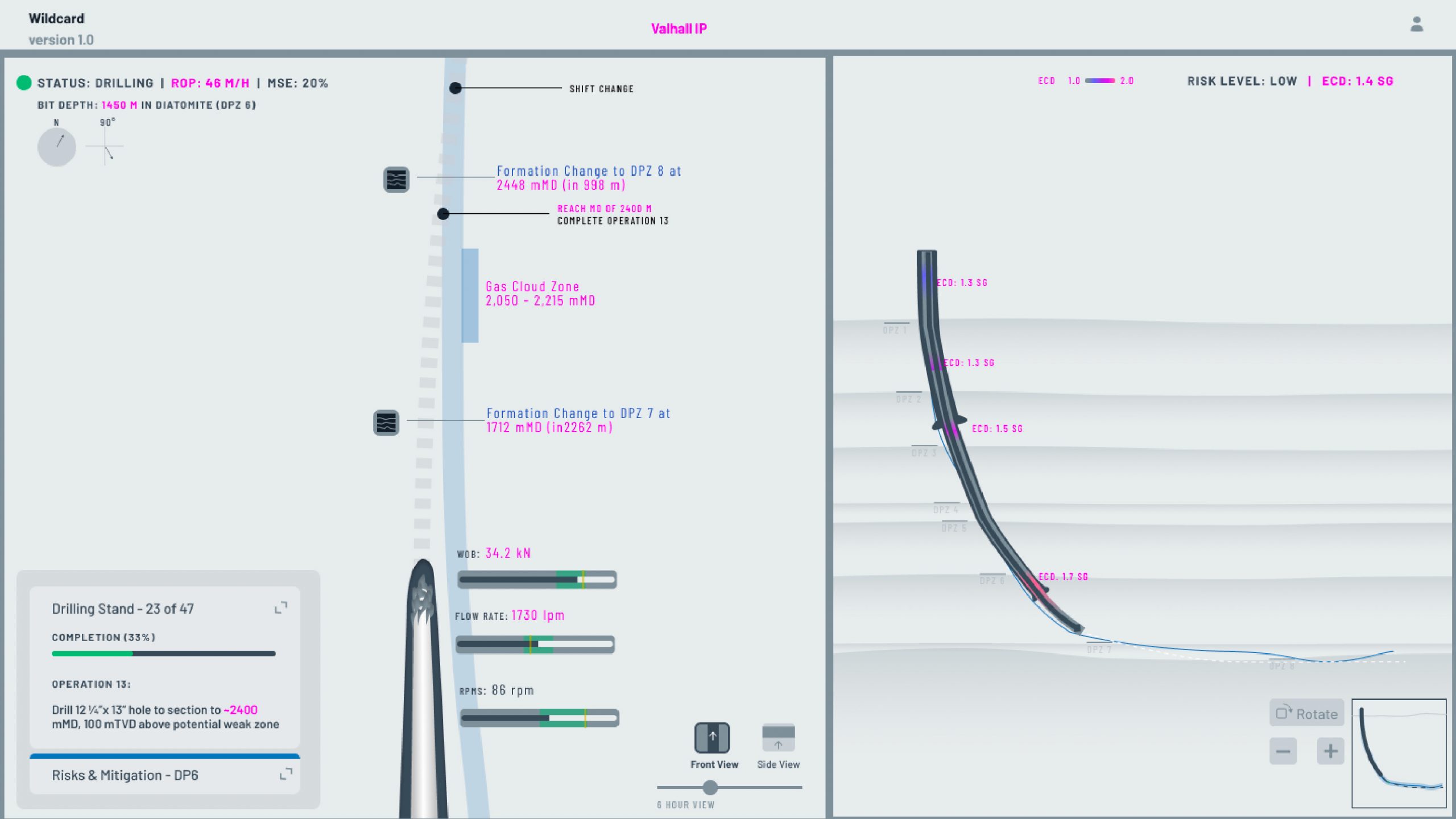

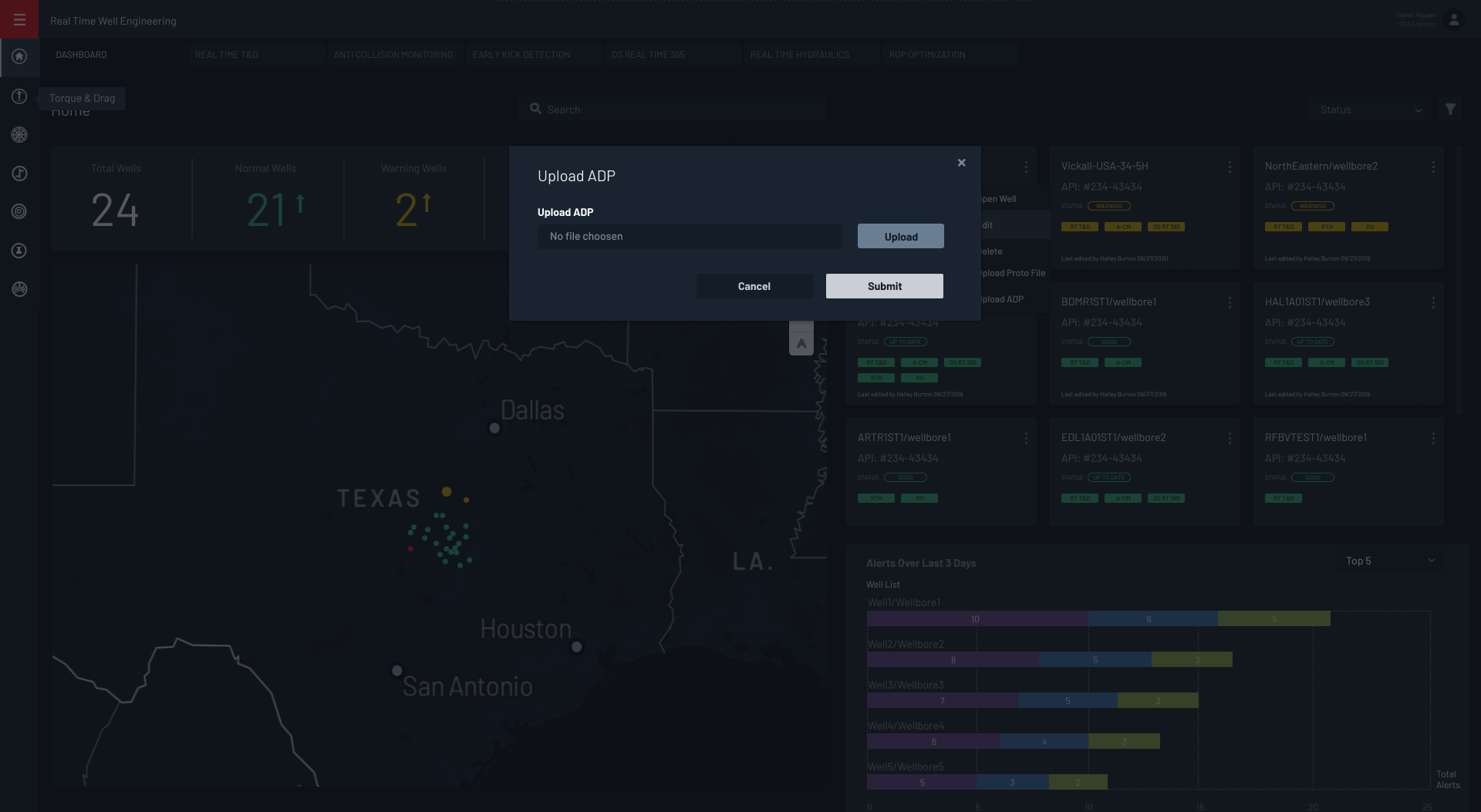

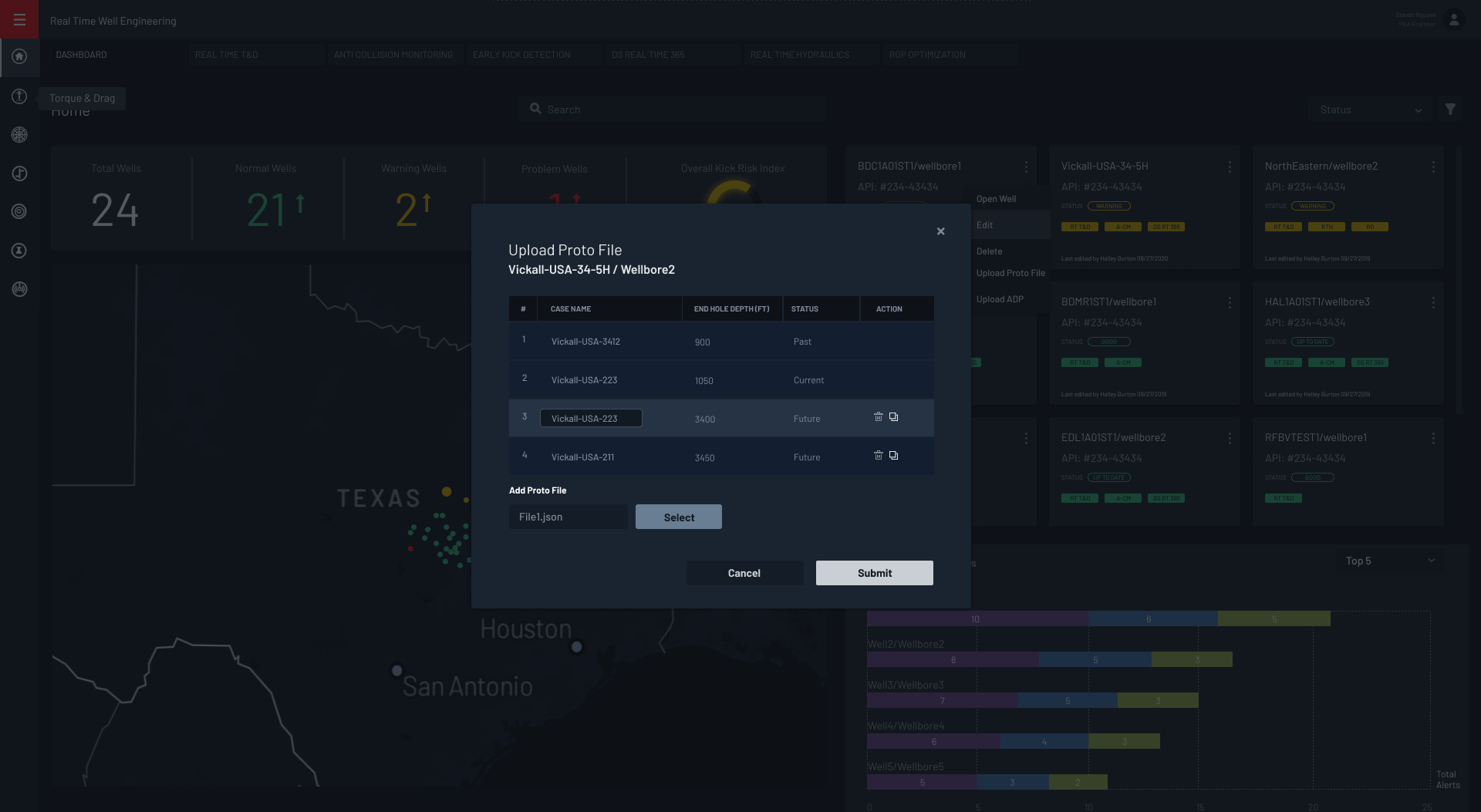

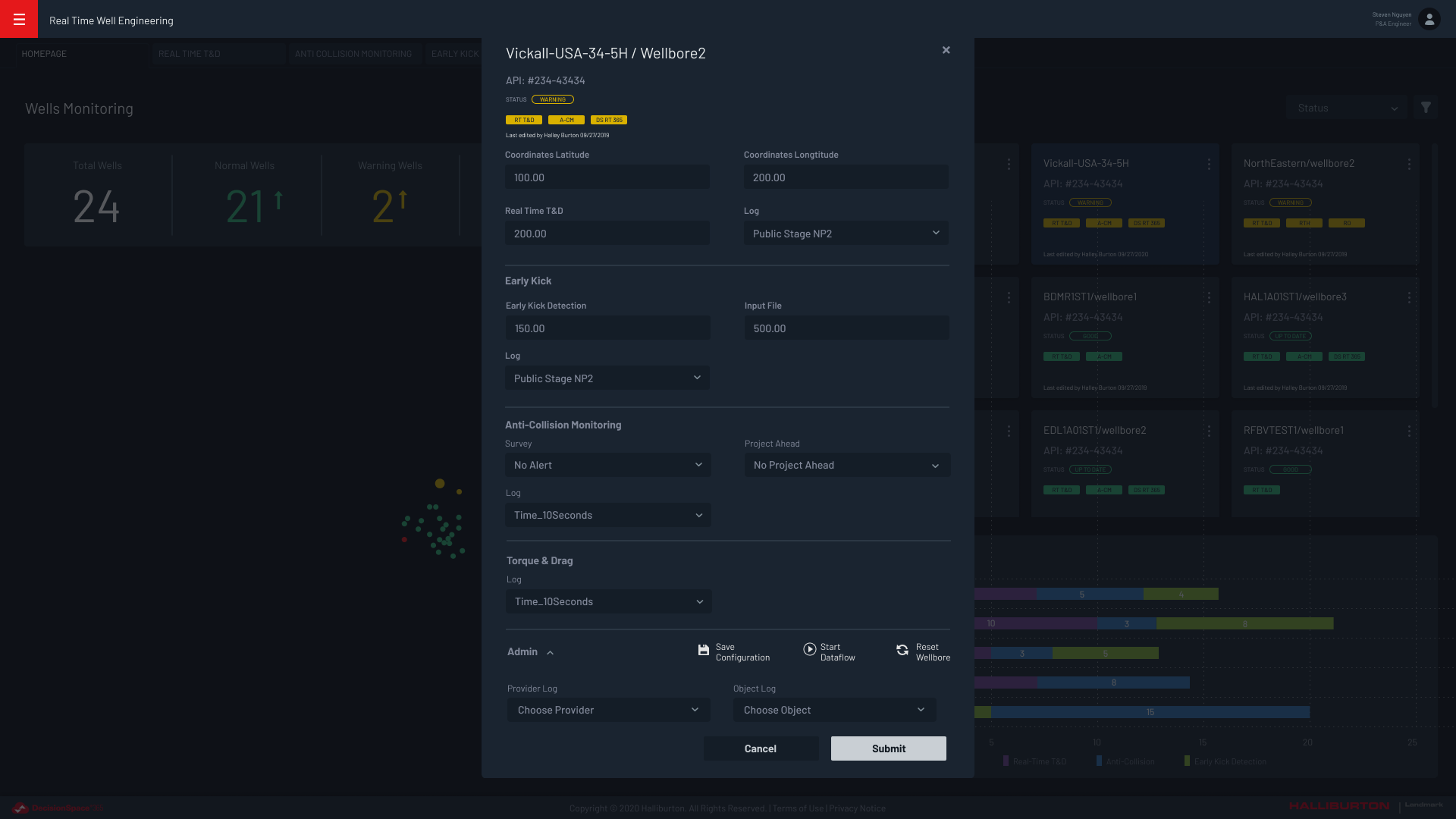

Home Dashboard:

- Focus on critical data: Prioritize real-time drilling parameters, sensor readings, and key performance indicators (KPIs) relevant to each user role.

- Organize data logically: Group related data points into meaningful categories and subcategories for easy navigation.

- Utilize visual cues: Employ color-coding, size variations, and other visual elements to highlight critical information and anomalies.

-

week 8-9-10

-

-

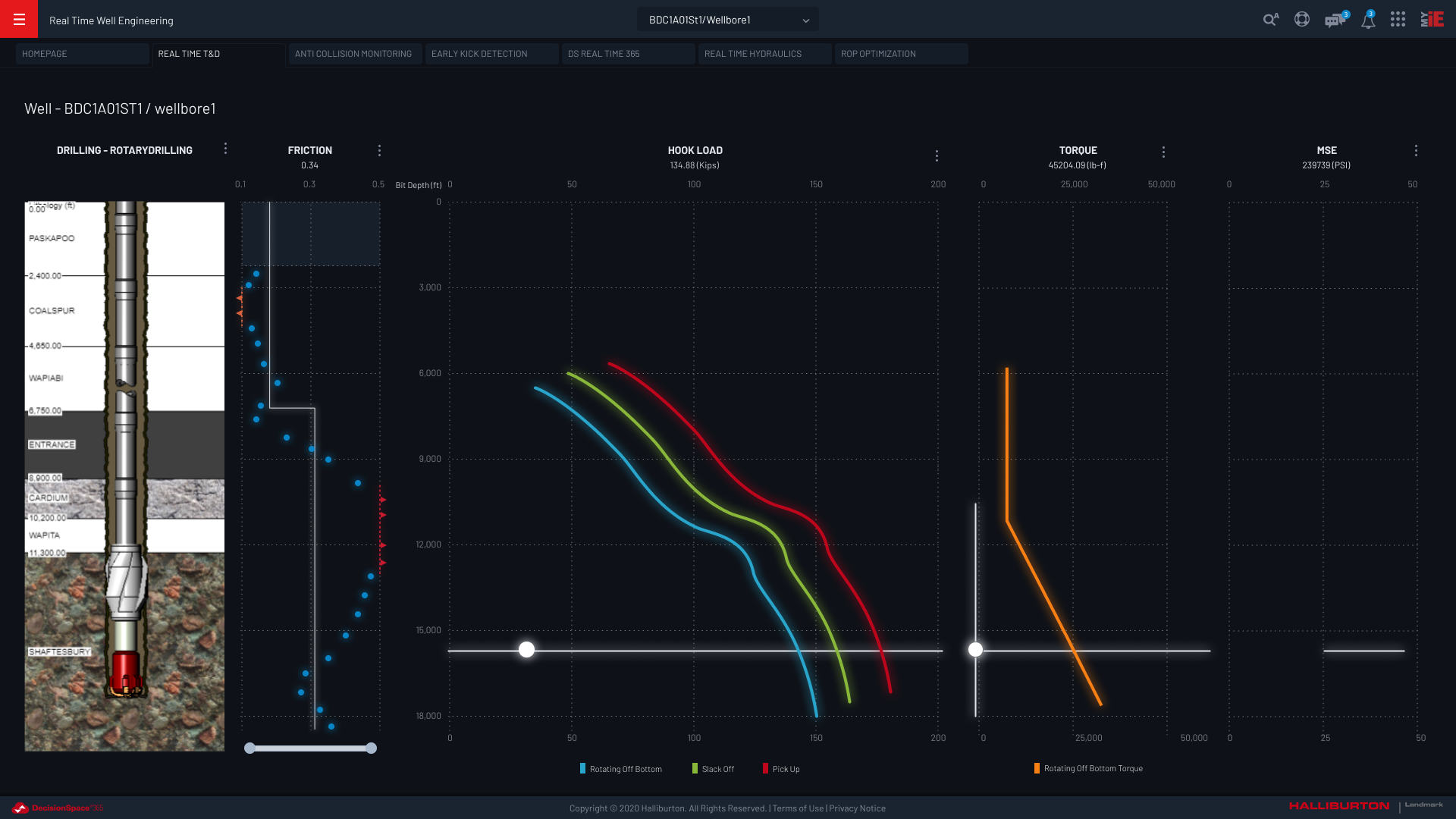

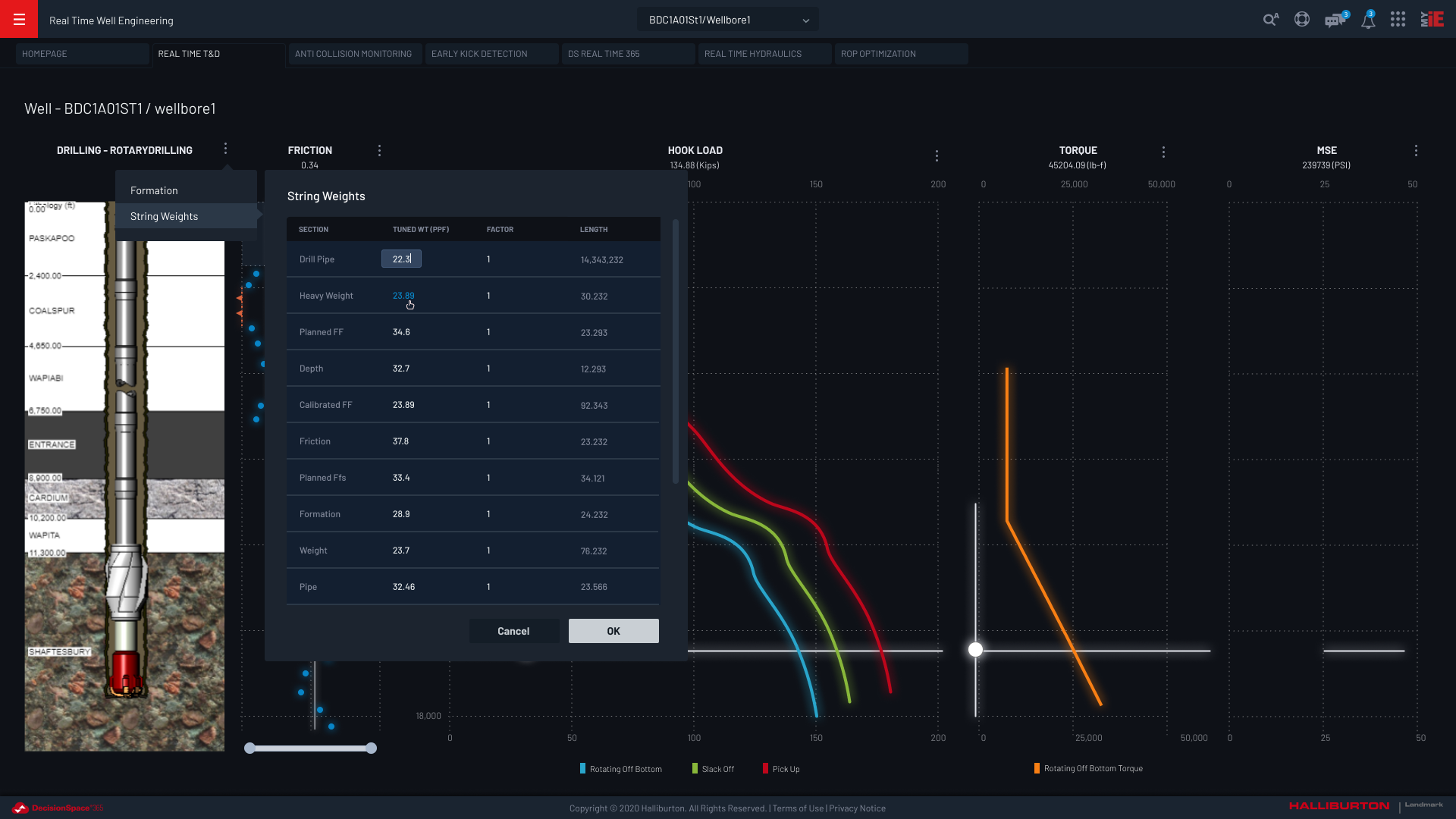

Realtime T&D:

- Clear and concise visuals: Use charts, graphs, and gauges that are easy to understand at a glance, even for users with limited data visualization experience.

- Interactive elements: Allow users to filter, zoom, and customize the data displayed on the dashboard for deeper exploration.

- Modular and flexible layout: Design a modular layout with customizable panels that users can arrange and resize to suit their preferences.

- 3D integration: Consider integrating relevant 3D wellbore visualizations seamlessly with the dashboard for holistic situational awareness.

-

week 8-9-10

-

-

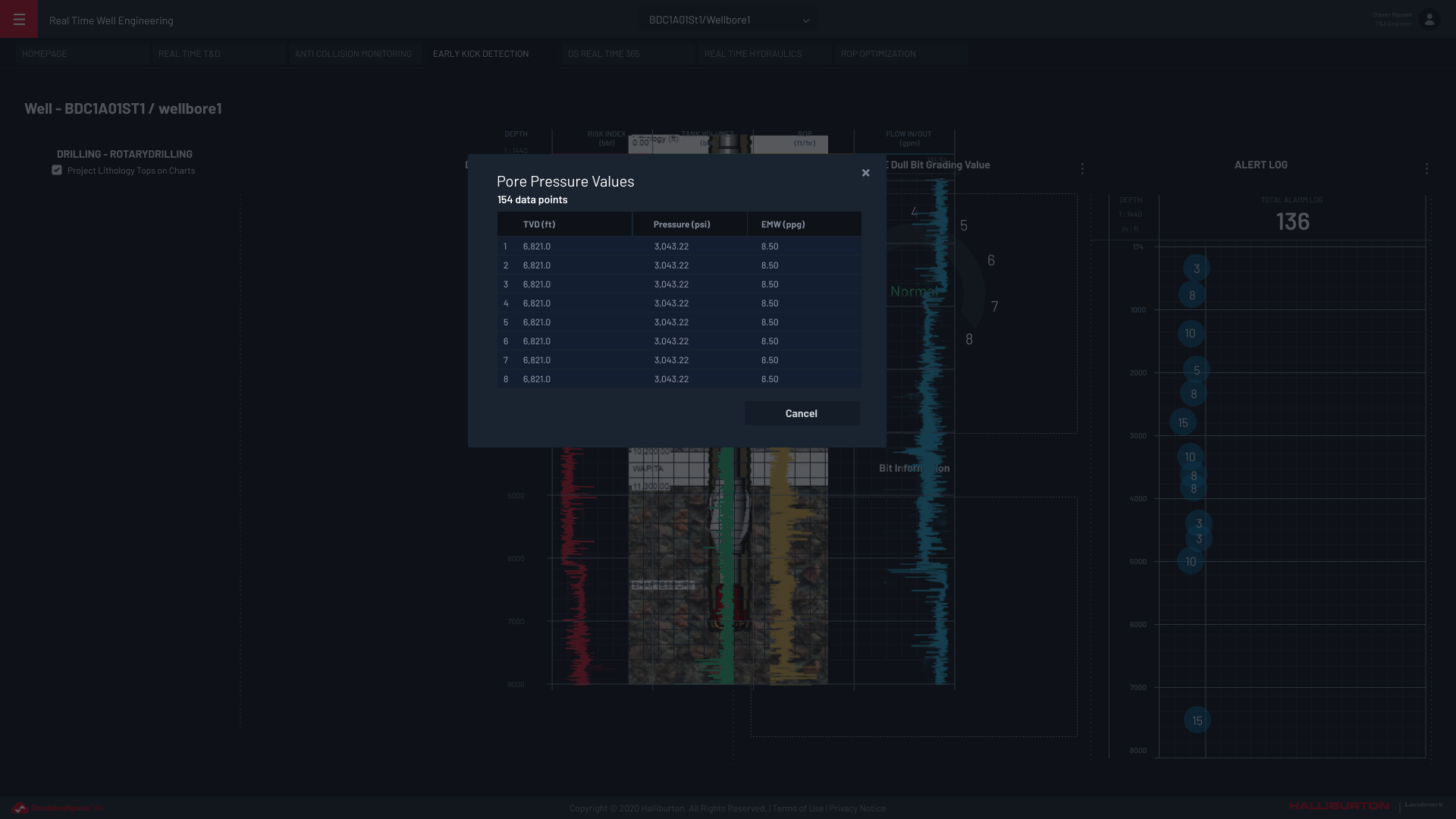

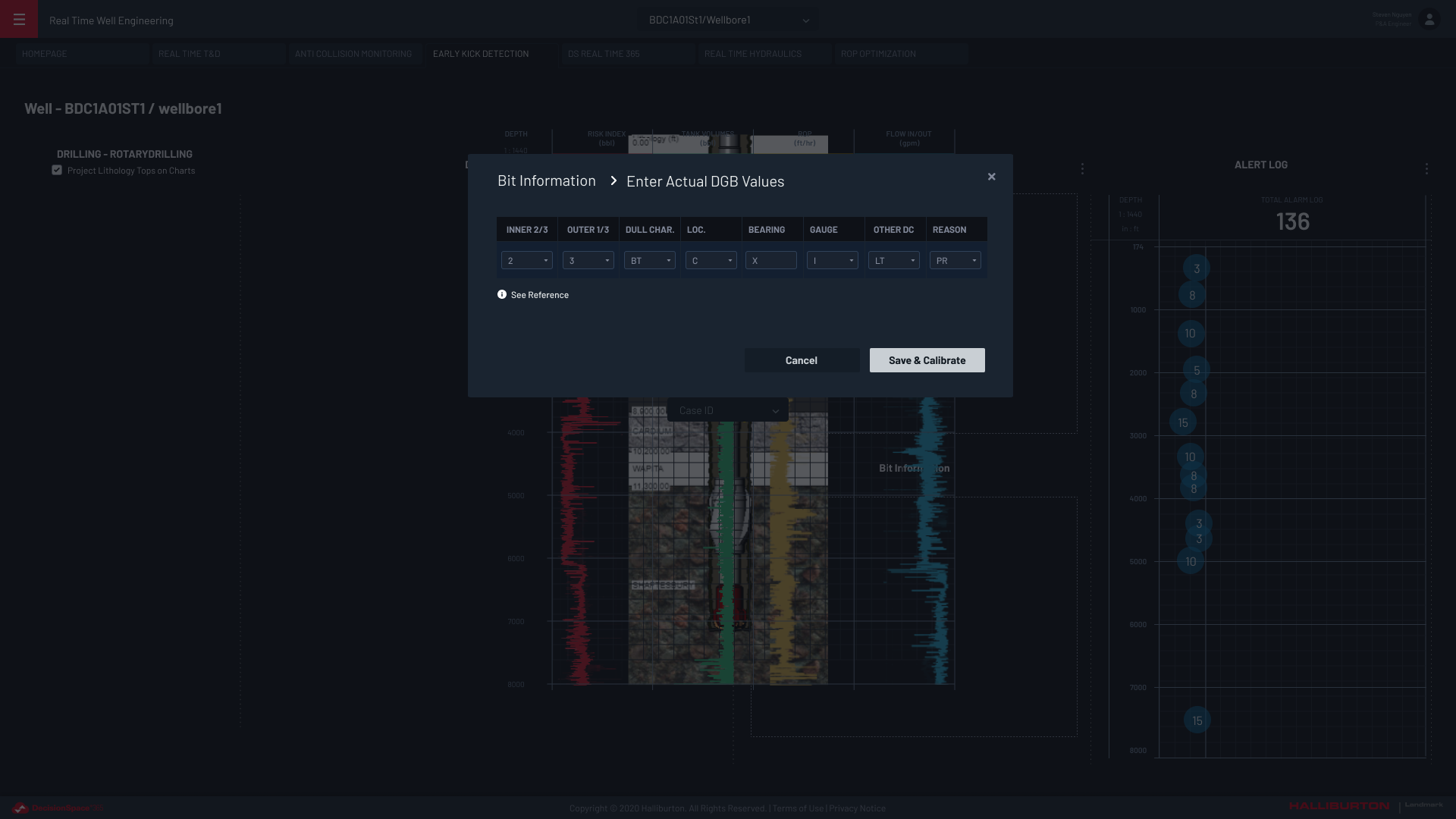

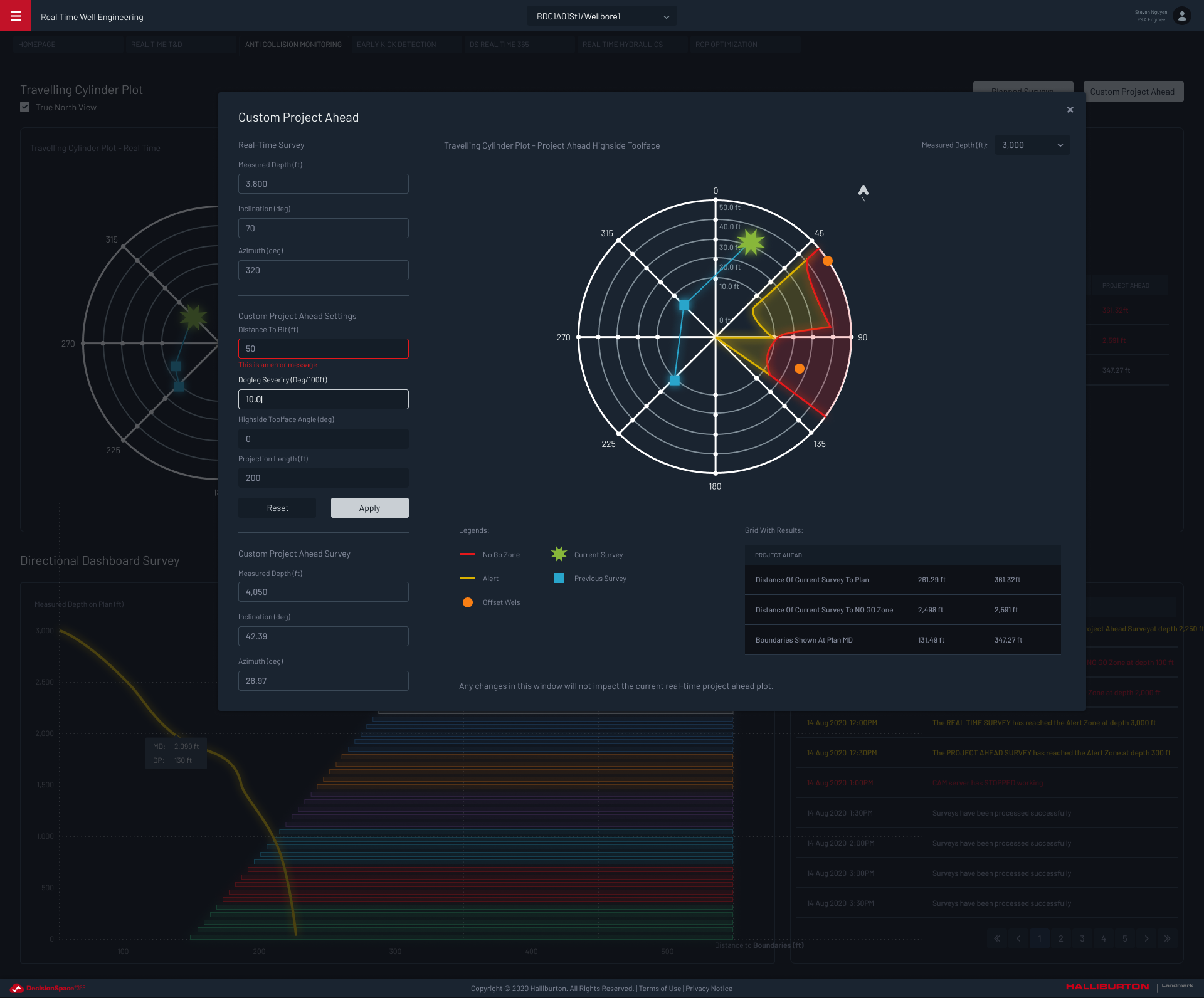

Anti Collistion and Bit Grading:

- Automated visualizations: Automatically update charts and graphs based on real-time data and set thresholds for triggering alerts.

- Customizable alerts: Allow users to define personalized alert conditions for critical events or parameter deviations.

- Time-based comparisons: Enable historical data comparisons to analyze trends and identify potential issues.

-

Production at HAL

Desired UI/UX Outcomes

- Improved situational awareness: Gain a clear and real-time understanding of downhole conditions, drilling progress, and potential risks.

- Enhanced decision-making: Provide data-driven insights and recommendations to support informed drilling decisions.

- Increased efficiency and productivity: Reduce manual tasks and optimize drilling operations.

- Improved collaboration and communication

- Enhanced safety and risk management: Identify potential hazards and enable proactive mitigation strategies.

- Reduced cognitive load

- Increased user satisfaction and adoption: Be Enjoyable and rewarding to use, leading to higher user satisfaction and widespread adoption.

Hypothetical data metrics

Track UI/UX effectiveness

- Time to identify critical events

- Decision-making accuracy

- Drilling time reduction

- Team communication frequency

- Safety incident rate

- User satisfaction surveys

- Eye-tracking data